PU round belt and PU V- belt welding method

A common and stable method for PU round belts and PU V- belts is to use high-temperature hot-melt connection, heating the belts at both ends to the melting point, and then quickly butting them together and applying pressure to bond them.

The specific steps are as follows:

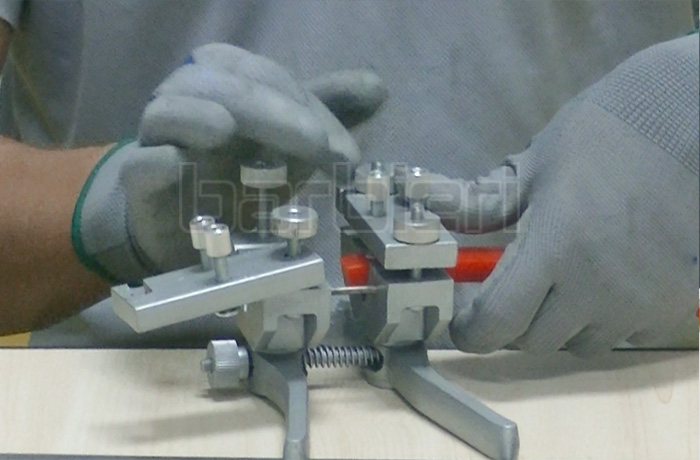

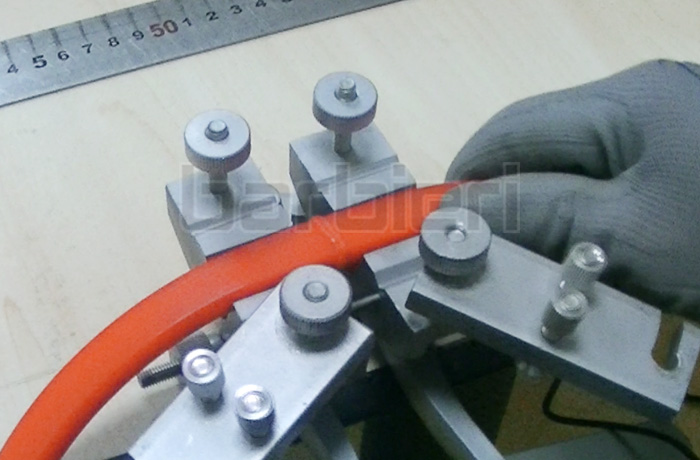

1. Prepare tools and materials: round belt or V-belt for connection, 3-piece set of joining tool (connection clamp, soldering iron, scissors)

2. Measure the length of the connected round belt or V-belt, and use scissors to cut the two ends of the belt flat.

3. Fix the cut round belt or V-belt on the connecting fixture, lock one side and fix it, the other side can be movable and adjusted, and lock it after alignment.

4. Use an electric soldering iron. After high temperature (just plug in the power for 8-10 minutes), align both sides and heat-melt weld.

5. After the round belt or V-belt is hot-melted, lock the splicing clamp for about 2-3 minutes, wait for the belt to cool and then disassemble the splicing clamp.

6.Take out the tape and inspect the welding joint to ensure that the welding quality is good, and then proceed to the next step to polish the welding joint smoothly.

If you have any needs, you can contact me to get detailed video operation instructions, PU round belt and Polyurethane V-belt welding methods.

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt