How to fix the timing pulley? What are the ways to fix the timing pulley?

The main purpose of fixing the timing pulley is to ensure the transmission stability between it and the shaft to avoid failure or sliding. The following are the common ways to install and fix the Timing belt pulley. No matter which fixing method is chosen, it is necessary to ensure that the connection between the synchronous pulley and the shaft is stable and reliable to prevent loosening or sliding caused by excessive transmission force or harsh working conditions, and avoid damage or failure.

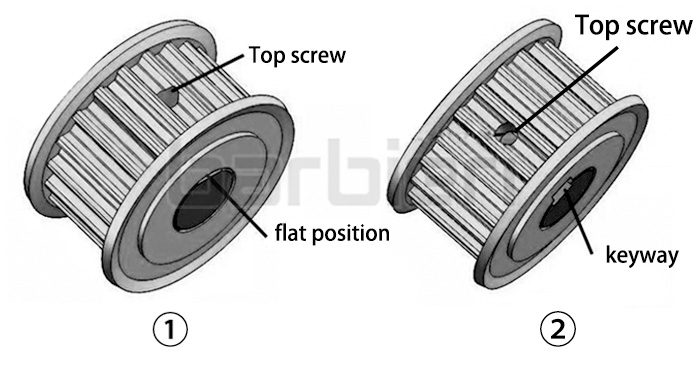

① Top screw + flat position: suitable for light load and low speed occasions.

Shaft flat position processing relies on top screw to press the flat position to transmit torque, which cannot withstand large torque and frequent forward and reverse rotation. The top screw will have the risk of loosening and slipping out, scratching the synchronous belt. If the burrs on the top screw hole of the synchronous wheel are not removed cleanly, the synchronous belt will be severely worn and broken after a short period of use.

② Top screw + keyway: suitable for medium and heavy load occasions.

The keyway of the synchronous wheel is matched, and the slots are made in the holes of the shaft and the synchronous pulley respectively, and then the two are connected by a key. This method can ensure the synchronous rotation between the synchronous pulley and the shaft to prevent it from sliding. It has a large transmission torque and a high speed. There is a risk of top screw sliding out and burrs on the hole mouth. Anti-loosening measures and burr cleaning are required.

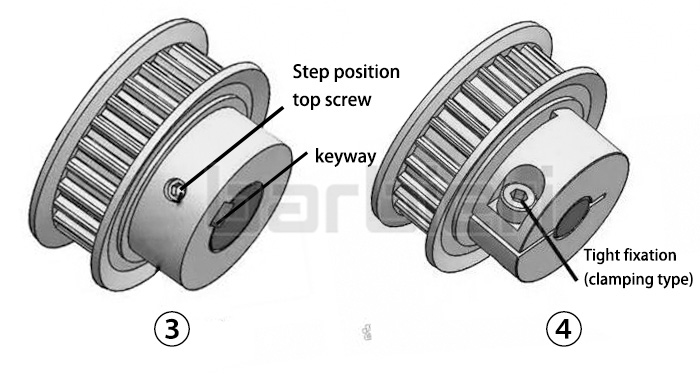

③ Step position top screw + keyway: suitable for medium and heavy loads, not suitable for some occasions with limited space.

The keyway of the timing pulley is matched, and the slots are made in the holes of the shaft and the synchronous pulley respectively, and then the two are connected by a keyway. This method can ensure the synchronous rotation between the synchronous pulley and the shaft to prevent it from sliding. It has a large transmission torque and a high speed. The top screw hole is moved to the external toothless shaft step. The top screw or top screw hole will not cause damage to the synchronous belt, but it is still necessary to pay attention to the loosening of the top screw. The step part increases the width of the synchronous wheel, which is not suitable for some occasions with limited space.

④ Tight fixation (clamping type): meets most usage occasions.

The timing pulley has a specially processed clamping structure, which can effectively fix the synchronous wheel and provide stable and reliable transmission force. This method does not require additional keyway or flat processing on the shaft, does not reduce the strength of the shaft, and has a large clamping torque.

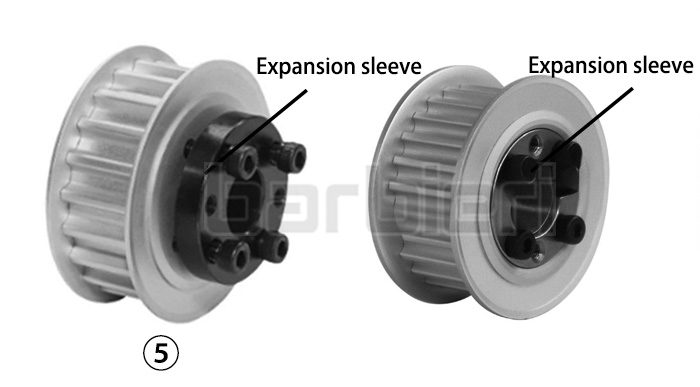

⑤ Keyless timing pulley: It can meet most occasions, but the disadvantage is that it increases the cost.

A tightening sleeve with inner and outer conical surfaces is placed between the shaft and the hub. By tightening the high-strength screws, the inner ring is reduced and the outer ring is expanded, so that the inner ring fits tightly with the shaft and the outer ring fits tightly with the hub, generating enough friction to transmit torque.