Timing pulley with anti-deviation function What pulley should be used to prevent belt deviation in automation equipment?

Deviation wear of the timing belt is the main failure mode in timing belt transmission. We can solve the problem by adding flanges to the timing pulley in the timing belt transmission or by using the auxiliary function of the guide rail design without flanges, so as to reduce the failure of the timing belt such as deviation wear.

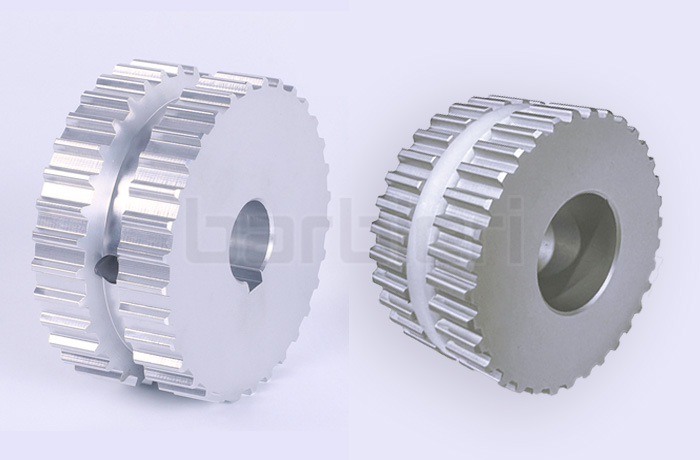

1. Timing pulley with retaining ring: physical feedback guides the center. During the synchronous belt transmission process, the existence of flanges can effectively limit the lateral movement of the synchronous belt, thereby preventing the synchronous belt from deviating.

One of the two timing pulleys can be used for transmission with flanges on both sides;

It is also possible to use two timing pulleys with single-side flanges on the opposite sides for transmission;

It is also possible to use the transmission method of flanges on both sides of two timing pulleys.

2. Timing pulley with groove: V or U-shaped groove with matching guide anti-deviation function of the timing belt, using the groove guide force to maintain the center track, increase stability and precision, combined application, optimize the belt conveying efficiency and stability, and drive smoothly to prevent deviation.

Timing belt with positioning and anti-deviation function and the matching timing pulley can effectively prevent the timing belt from deviating during the transmission process.

The deviation of the timing belt also requires careful inspection and adjustment of the drive system. Through correct installation, adjustment and maintenance, the deviation of the timing belt can be reduced and production efficiency can be improved.

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt