Are the timing belt and timing pulley any match? Timing belt and timing pulley meshing conditions

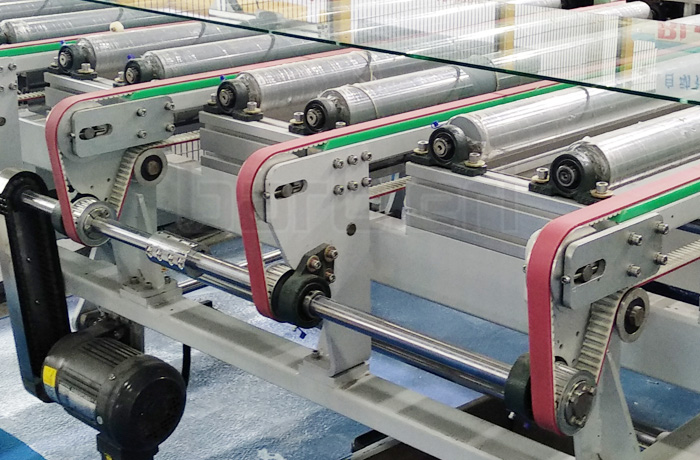

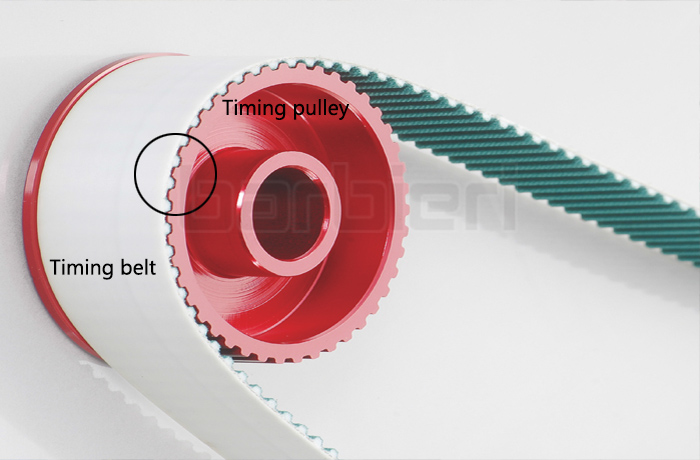

Timing belt and the Timing pulley are not randomly matched. The tooth shapes of the timing belt and the timing pulley must match (for example: AT10 timing belt and AT10 timing pulley are used together). The tooth shape of the timing belt is specific. The tooth profile of the pulley must also match it to ensure the correct meshing between the belt and the wheel to transmit torque and power. If the tooth profile does not match, it will cause the transmission to be uneven, slipping or even breaking.

The conditions for the smooth meshing of the timing belt and the timing pulley mainly include: the pitch of the timing pulley and the timing belt are equal, and there is a circle on the timing pulley that is tangent to the pitch line of the belt, and pure rolling is achieved during operation. If the circle If the wiring is not tangent to the belt, poor meshing of the timing belt and pulley will occur.

Secondly, the size of the timing belt and the timing pulley also need to match. Proper size matching can ensure the correct installation and tensioning of the belt on the pulley to avoid being too tight or too loose. Too tight may cause increased belt and wheel wear, while too loose may cause transmission failure.

In addition, the materials of the timing belt and timing pulley also need to be considered. Different materials and combinations may have different effects on the performance of the transmission system. Some materials may provide better wear resistance and durability, while others may provide better transmission efficiency. When selecting timing belts and timing pulleys, you need to consider whether their materials are suitable for the specific application and environmental conditions.

Finally, the matching of the timing belt and the timing pulley also needs to consider the transmission ratio and rotation speed. Different transmission ratios require different combinations of timing belts and pulleys. Excessive rotation speed may cause increased wear of the belt and pulleys, so it is necessary to Choose a timing belt and pulley that is suitable for the rotational speed.

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt