Commonly used tensioning methods for timing belts

Timing belt transmission structure is usually designed with a tensioning method to ensure that the timing belt maintains appropriate tension during operation, thereby ensuring the efficient, stable and reliable operation of the timing belt transmission system. In the design of the timing belt transmission system Common timing belt tensioning methods are as follows.

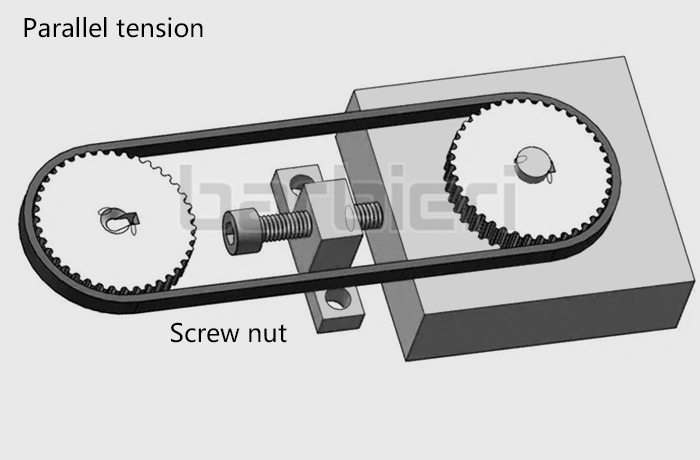

1. Parallel tensioning method

Tensioning is achieved by pulling two synchronous belts. There is no external tensioning structure, and the tensioning structure is also very compact. The characteristic of this method is that there is no need to add redundant mechanisms, which can save assembly costs and reduce failure rates. Mechanical moving parts The less, the more stable it is.

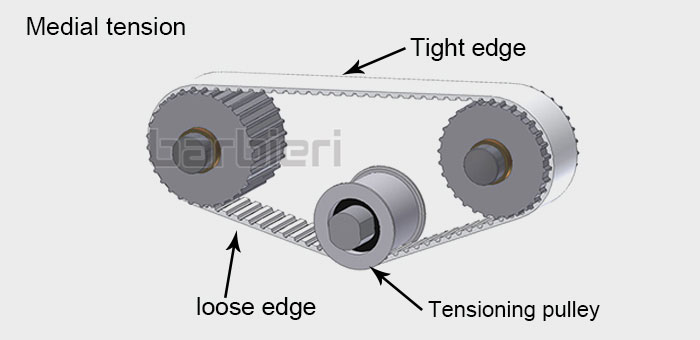

2.Medial tensioning method

The inner tensioning pulley can be a smooth idler wheel without teeth or a synchronous idler wheel with teeth. The tooth surface of the synchronous belt contacts the smooth surface of the idler wheel. In comparison, the use of a synchronous wheel will have a better effect, but the cost will also be higher. In addition, the inner tensioning mechanism will make the synchronous belt protrude, thereby increasing the space, which is not suitable for compact scenes.

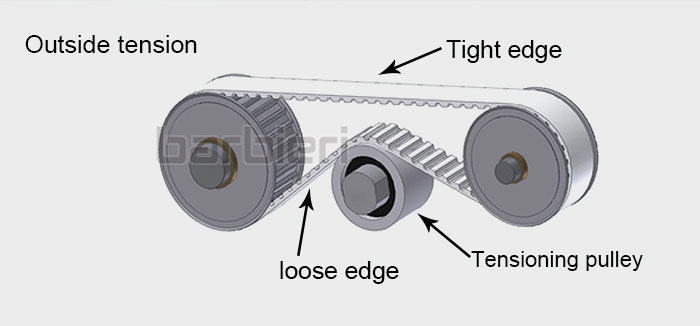

3.Outer tensioning method

It is suitable for low speed and low acceleration conditions. It actually uses a combination of sliding friction and rolling friction. The surface of the timing belt is susceptible to wear and tear, resulting in surface flatness, grinding and other problems.

The use of tensioning pulleys should be minimized in mechanical design, because the tensioning pulleys in the synchronous belt drive will have a certain impact on its service life. It is recommended that the timing belt tensioning pulleys be installed on the loose side of the transmission instead of the tight side, so as to achieve better results.

In short, when selecting the timing belt tensioning method, factors such as the actual needs of the transmission system, working environment, cost and maintenance requirements need to be comprehensively considered. At the same time, it is also necessary to pay attention to the impact of the tensioning method on the transmission efficiency and service life of the timing belt to reasonably design the tensioning method.

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt