Commonly used timing belt structure types in automation equipment

Timing belt transmission is a meshing transmission composed of a timing belt and two or more timing pulleys, and its synchronous motion is transmitted through the meshing of the belt teeth and the teeth.

Transmission of motion and power between two pulleys

This is the most widely used

Generally, it is necessary to add a belt tensioning mechanism.,The commonly used tensioning mechanisms are:

1. Use the waist hole to adjust the position of the driving wheel or the driven wheel, and increase the center distance to tension the timing belt.

2. Add a tensioner mechanism outside the synchronous belt to compress the belt and tension the belt.

3. Add a tensioning mechanism inside the synchronous belt; the inner tensioning wheel can be an idler or a synchronous pulley. It is better to use a synchronous pulley, because with an idler, the tooth surface of the synchronous belt and the smooth surface of the idler contact, there will be vibration and noise.

Multi-pulley serial transmission

This way requires fewer components, compact structure, and easy design. With this structure, the center distance between the pulleys is related to the timing belt length, and the center distance tolerance should be a positive tolerance. And all pulleys are suitable for single rib pulleys. However, it is difficult to arrange and tension, and maintenance is troublesome, and the load of each synchronous belt is uneven.

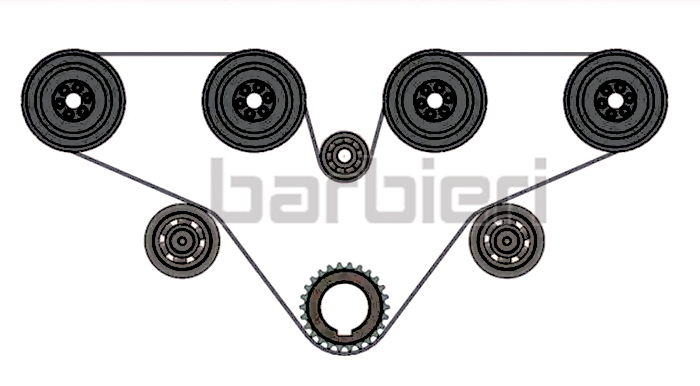

Multi-wheeled Ω structure

In this form, only one synchronous belt can be used, which is convenient for arrangement,tensioning and debugging, with light noise and high transmission speed,But processing and installation requirements are higher.

The tensioning mechanism of this structure can be to adjust an idler wheel with elastic tensioning mechanism or waist hole adjustment tensioning mechanism or eccentric rotation adjustment mechanism.

Because the synchronous belt is folded many times in this structure, the rubber synchronous belt is more suitable.

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt