Difference between single-sided tooth timing belt and double-sided tooth timing belt

Double-sided toothed timing belts and single-sided toothed timing belts each have their own advantages. It is necessary to comprehensively consider factors such as application situations, equipment transmission methods, required precision load-bearing, etc. to choose double-sided toothed or single-sided toothed timing belts in their respective fields. Play a bigger role.

Tooth structure:

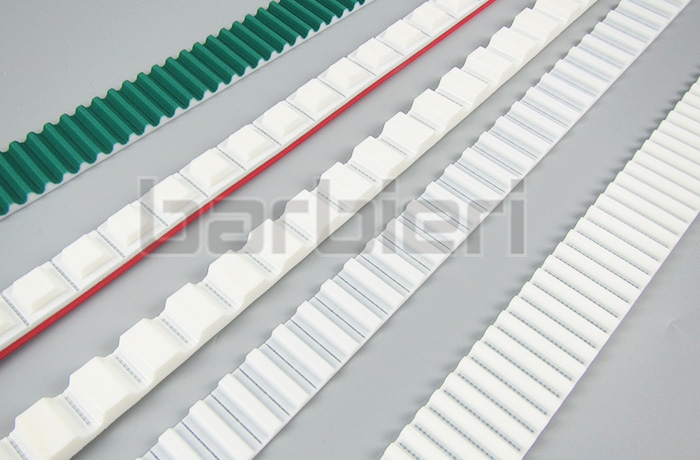

The single-sided toothed timing belt has a single-sided tooth structure and can only transmit power and torque in one direction; the double-sided toothed timing belt has a toothed structure on both sides to achieve simultaneous transmission on both sides.

Transmission efficiency:

The double-sided toothed timing belt has high transmission efficiency. Because it has a double-sided toothed structure, it can achieve double-sided transmission, so the transmission efficiency is higher than that of a single-sided toothed timing belt.

Carrying capacity:

The double-sided toothed timing belt has a higher load-bearing capacity. Since the double-sided toothed structure can disperse and carry the load well, it can better resist bending or stretching forces during the transmission process, so the load-bearing capacity is relatively high. It has a stronger load-carrying capacity than a single-sided toothed timing belt.

Transmission accuracy:

Double-sided toothed timing belts have higher transmission accuracy. Since the double-sided toothed structure can ensure better synchronization and accuracy, the rotational speed error during the transmission process is smaller, so the transmission accuracy is compared with single-sided toothed timing belts. The belt is more accurate.

Cost and maintenance: Due to the relatively simple single-sided tooth structure, single-sided toothed timing belts have lower manufacturing costs and are more convenient to install and maintain. Single-sided toothed timing belts, with their simple design and low manufacturing costs, Widely used in various transmission equipment with excellent performance, single-sided tooth timing belts can meet most needs.

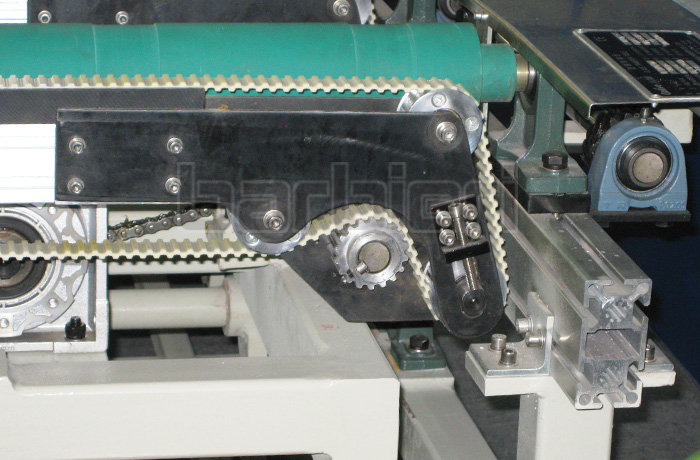

Double-sided tooth timing belts provide higher transmission stability and load-bearing capacity due to their double-sided tooth structure. They are especially suitable for applications that require high precision and heavy loads. The key to choosing between double-sided teeth and single-sided teeth lies in the application. By comprehensively considering factors such as the scene, the transmission mode of the equipment, the required accuracy, and the load-bearing capacity, double-sided tooth timing belts and single-sided tooth timing belts can play a greater role in their respective fields.

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt