Gear Drive &Chain Drive & Belt Drive

Common transmission mechanisms in mechanical engineering include gear drive, chain drive and belt drive, and each transmission mechanism has its own characteristics. When choosing a transmission method, comprehensive consideration should be given to factors such as actual application requirements, environmental conditions and economic costs. Reasonable selection of these transmission methods can ensure the stable operation and efficient work of the mechanical system.

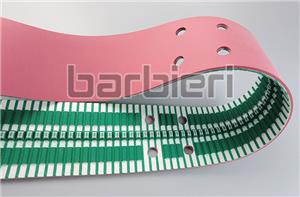

1. Timing belt drive (a type of belt drive) is a synchronous transmission between the timing belt and the timing pulley through meshing. The transmission is accurate, stable and efficient, with a certain buffering and shock absorption ability, and the noise generated is small. It summarizes some advantages of gear drive, chain drive and belt drive. It can not only be used for short-distance transmission, but also has long-distance transmission capabilities.

In terms of maintenance and maintenance, the maintenance and maintenance of the synchronous belt drive system is relatively convenient, because its structure itself does not require lubrication, thereby avoiding the pollution problem that may be caused by lubrication, and the maintenance cost is low.

2. Gear transmission is to transmit power and torque through the meshing of two or more gears. One gear drives another gear to transmit power. Gears can realize transmission between parallel axes and any staggered axes. Gear transmission has the characteristics of accurate transmission, high efficiency, compact structure, reliable operation and long life. However, it is not suitable for transmission between two axes at a long distance, and there are also large noise and vibration.

In terms of processing accuracy and cost, the processing accuracy and cost of gears are relatively high.

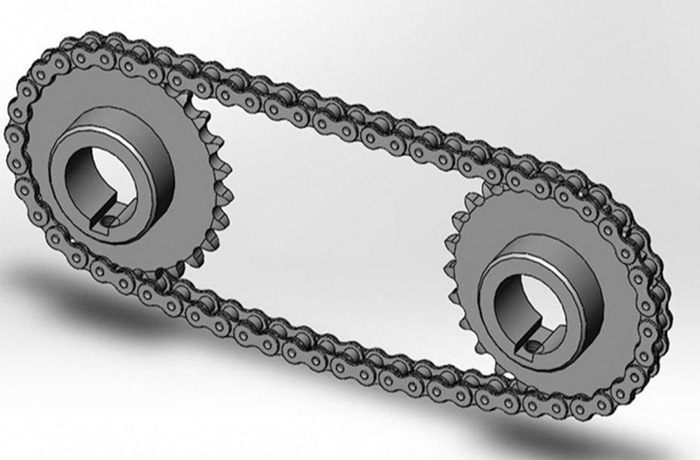

3. Chain transmission uses the meshing of chain and sprocket teeth to transmit power and motion. The transmission is accurate and the transmission distance is relatively long. Compared with belt transmission, chain transmission has no elastic sliding and slipping phenomenon, large transmission power, strong overload capacity, and can work in harsh environments such as high temperature, humidity and dust. However, chain transmission can generally only be used for simple mechanical transmission between two parallel axes, with poor transmission stability, easy to wear the chain, and easy to decouple.

In terms of processing accuracy and cost, the processing accuracy and cost of sprockets are relatively low.

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt