How high a temperature can a polyurethane timing belt withstand? How to improve the high temperature resistance of a PU timing belt

The normal temperature resistance range of a polyurethane timing belt is -10℃ to +60℃. Within this temperature range, the polyurethane timing belt can maintain good transmission performance and service life (can withstand up to 80℃ in a short time)

Polyurethane timing belt temperature resistance characteristics:

Elasticity decreases and hardness increases above 80℃;

Above 100℃, aging is accelerated, and the tooth shape may be deformed, affecting its service life and transmission efficiency;

Above 120℃, mechanical properties are lost and there is a risk of breakage.

Rubber timing belts are more resistant to high temperatures than polyurethane timing belts. The normal operating temperature of rubber timing belts is -35℃ to +80℃ (can withstand up to +115℃ in a short time), but rubber timing belts will generate dust during operation, so many customers choose polyurethane timing belts.

In special applications, in order to further improve the heat resistance of polyurethane timing belts, heat-resistant felt, silicone, etc. are added to the back of the timing belt that is exposed to high temperatures. These additional materials can improve the heat resistance of the timing belt to a certain extent and extend the service life of the timing belt in a high temperature environment.

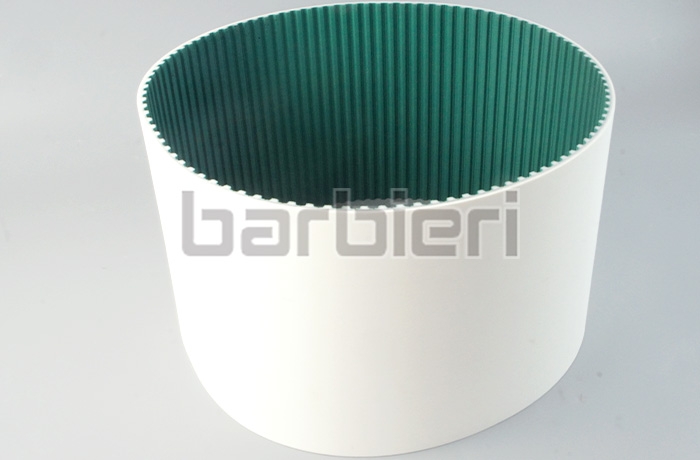

Various types of silicone timing belt

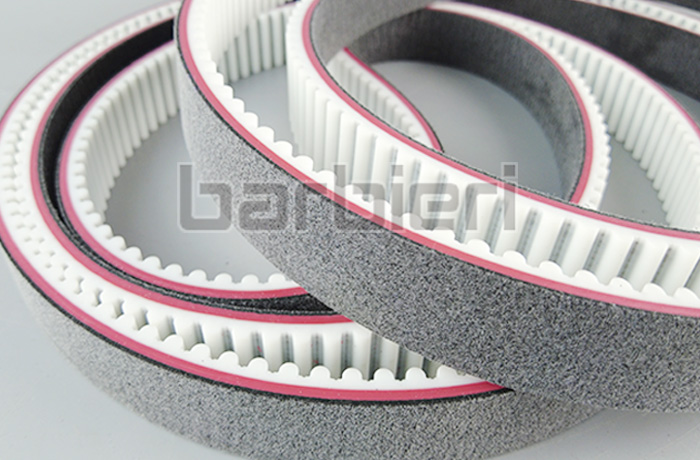

Felt or silicone made of heat-resistant material is added to the back of the timing belt that is exposed to high temperature. After processing, the timing belt is also called felt timing belt or silicone timing belt. Felt timing belt and silicone timing belt are both commonly used methods to improve the heat resistance of synchronous belts. Felt has good thermal insulation properties and can reduce the transfer of heat to the inside of the timing belt. Silicone has excellent high temperature and chemical resistance and can maintain stable performance in high temperature environments.

Various types of felt timing belt

The use of additional materials such as felt timing belt and silicone timing belt needs to be selected according to the specific application environment and requirements. In actual applications, it is necessary to select appropriate timing belt materials and additional materials according to specific working conditions and performance requirements to ensure efficient operation and long-term stability of the equipment.

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt