How to accurately position the timing belt to achieve high-precision automatic reciprocating positioning and conveying

Automated production lines achieve high-precision reciprocating positioning and conveying. At this time, accurate control and positioning of the timing belt are crucial. By installing metal false teeth on the timing belt, or installing blocks on the timing belt, and adding nuts and accessories to the ATN series timing belt, these specially processed timing belts can be accurately positioned and become key components of the automated production line, so that parts can be processed and assembled at the right time and position, achieving the effect of high-precision positioning and conveying, greatly improving production efficiency and product quality.

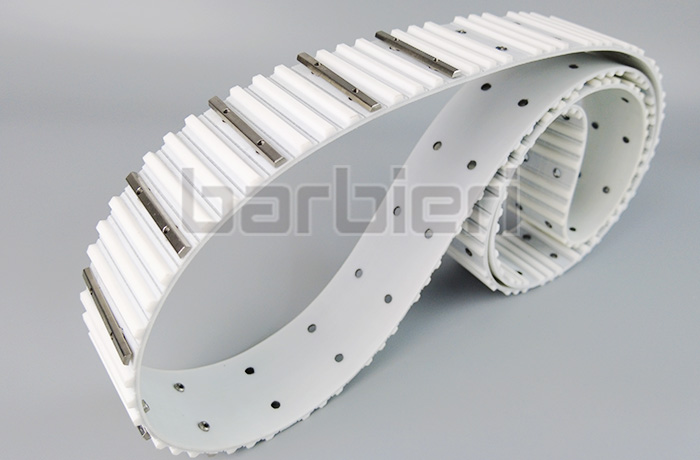

1. Timing belt false teeth installation (Timing belt with false teeth)

The metal false tooth timing belt is a special design selection. The timing belt is removed and punched, and then a special stainless steel false tooth is installed. The false teeth are consistent with the tooth structure of the timing belt. The false teeth have threaded holes for fixing accessories. The false teeth have high hardness and strong wear resistance, and are suitable for high-precision and high-load transmission systems.

The false tooth timing belt STD8M/T10/AT10/H/T20/AT20 can choose full tooth design or embedded tooth setting.

2. Timing belt welding cleat (Timing belt with cleat)

Installing cleat on the timing belt is another effective way to achieve high-precision positioning. The cleat can be designed and processed into various shapes according to actual needs. During the conveying process, the cleat can accurately position the material at the predetermined position to prevent the material from shifting or moving. It can also be used as a trigger signal to cooperate with the sensor to achieve automatic control and monitoring.

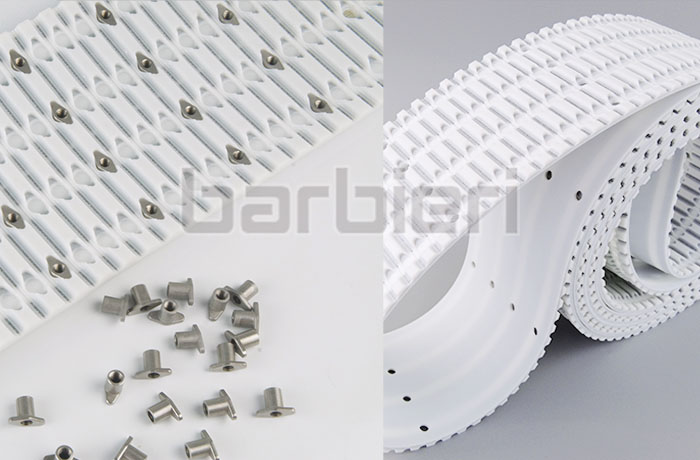

3. Timing belt welding with cleat with nut (Timing belt with nut cleat)

The cleat with embedded nut is welded on the back of the timing belt at the required spacing. The cleat with embedded nut can be installed with accessories to meet the needs of shipping, pushing, lifting or starting. This design enables the synchronous belt to run stably in the automated assembly system and is suitable for assembly, packaging and other scenarios.

4..Application of ATN timing belt plus nut plus accessories

The commonly used models of ATN series timing belts are ATN10 and ATN20, which are also timing belts designed for high-precision transmission. The surface of the diamond countersunk timing belt has a special nut structure. After drilling holes according to the needs of use, the nuts can be installed to connect with various types of accessories. There is no error in the spacing, and the accessories can be adjusted according to the tooth pitch according to the needs of use. By installing suitable accessories, such as positioning blocks and guide blocks, the positioning accuracy and stability of the timing belt can be further improved. The combination of ATN series timing belts, nuts and accessories is suitable for various complex and high-demand transmission systems.

In addition to the special processing design of the timing belt, the realization of high-precision automatic reciprocating positioning and conveying also requires comprehensive consideration of the overall design and adjustment of the system, including the tension of the timing belt, the control accuracy of the drive motor, the sensitivity and position of the sensor, etc. Through precise calculation and debugging, ensure the coordination between various components to achieve high-precision positioning transmission effect.