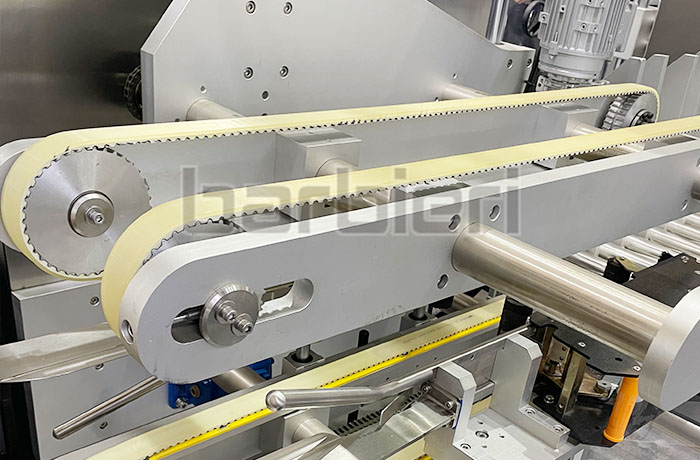

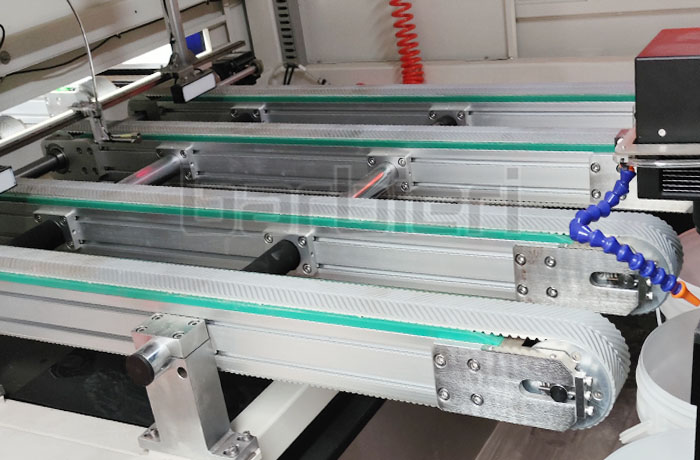

How to correct the parallelism of the timing belt and timing pulley

Timing pulley parallelism refers to the parallelism between the two wheel axes. If the parallelism does not meet the requirements, the timing belt will move sideways to increase friction, causing energy loss and increased noise, and even causing problems such as wear and breakage of the timing belt. It can be corrected by using a level, ruler or laser alignment. By comparing the standard or directly measuring the parallelism error on both sides of the synchronous belt, the position of the two wheels is adjusted to make the two axes of the two wheels parallel in a straight line.

1. Visual measurement

It is to observe the installation of the timing belt on the driving and driven pulleys with the naked eye to see if there is obvious distortion or deflection. This method is simple and easy, but the accuracy is limited and can only be used as a preliminary inspection.

2. Level measurement

The level is one of the commonly used measuring tools. Place the level on the pulley axis to ensure that the level is perpendicular to the axis, and then observe whether the bubble of the level is in the center. If the bubble is offset, it means that the pulley is tilted. In order to be more accurate, the level can be placed in multiple positions for measurement. If the tilt is large, it needs to be adjusted to ensure that the pulley is level.

3. Ruler measurement

A ruler can also be used to measure the parallelism of pulleys. Select two mutually parallel reference points and use a ruler to measure the distance from the edges of the two pulleys to the reference points. If the two distances are equal, the pulleys are parallel; if the distances are not equal, there is a parallel misalignment. For more accurate measurement, measurements can be made at multiple locations of the pulley. If the parallel misalignment is large, adjustments need to be made to ensure that the pulleys are parallel.

4. Laser Alignment

The laser alignment instrument is a high-precision measurement tool. The laser beam is a straight line. The alignment tool consists of two components, one component emits the laser and the other reflects the laser back to its origin. If misalignment is found, it is adjusted according to the laser position.

In short, correcting the alignment angle and measuring parallelism are indispensable steps in the installation of synchronous belt. Through precise measurement and adjustment, we can ensure the stable operation and efficient performance of synchronous belts in the transmission system.

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt