Reasons and measures for the frequent falling of the flange of the timing pulley during use

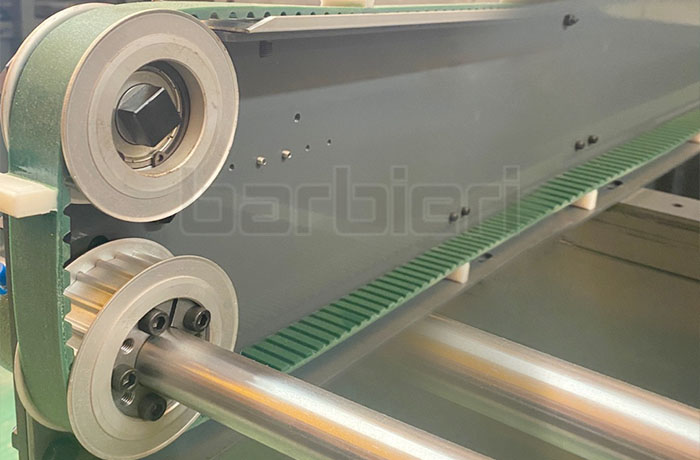

The flange of the timing pulley (also known as the retaining ring or retaining edge) is installed to prevent the timing belt from deviating or falling off. Why does the retaining edge fall off during the use of the timing pulley?

The main reasons for the fall of the retaining edge of the timing pulley are as follows:

1. The timing belt deviates for a long time: The main function of the flange is to prevent the timing belt from falling due to deviation during operation. When the timing belt is in a deviated state for a long time, the edge will produce continuous friction and extrusion with the flange, and eventually cause the retaining edge to fall due to excessive force.

2. Improper installation: The installation accuracy of the timing pulley has a direct impact on the stability of the flange. If the installation axes of the timing pulley are not parallel to each other during the installation process, or the installation accuracy does not meet the requirements, the timing belt will be offset during operation and aggravate the wear and fall of the retaining edge.

3. Equipment aging and insufficient maintenance: As the equipment is used for a longer time, the timing belt and flange will naturally wear and age. If the severely worn timing belt is not replaced in time or the damaged flange is not repaired, the flange will be more likely to fall off during operation.

Measures to prevent the flange of the timing pulley from falling off:

1. Regularly check the equipment: The operating status of the timing belt should be checked regularly. Once the timing belt is found to be deviated or worn, measures should be taken to adjust it in time.

2. Ensure installation accuracy: When installing the synchronous wheel, ensure that the parallelism and accuracy of the installation shaft meet the requirements, and ensure that the timing belt can remain stable during operation.

3. Strengthen equipment maintenance: Regularly maintain the equipment, replace the severely worn timing belt and repair the damaged flange in time, and pay attention to check whether the transmission parts and support structures of the equipment are stable and reliable to avoid the deviation of the timing belt due to loose or damaged equipment.

4. Choose high-quality timing belt: When purchasing timing belts, you should choose products with reliable quality and stable performance to ensure that the force can be evenly applied during use and reduce the occurrence of deviation.

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt