Timing belt failure forms and causes

The timing belt and the timing pulley mesh with each other to transmit power. During use, the timing belt may fail for various reasons. The following examples illustrate some of the most common failure modes so that preventive measures can be taken to extend the service life of the timing belt.

Failure form | Photo | Status | Analysis |

Normal failure |

| The rope core reaches the fatigue life, and the synchronous belt breaks in a jagged 45-degree angle. | The timing belt reaches its ultimate tensile fatigue and failure after 2-3 years of operation is considered normal. |

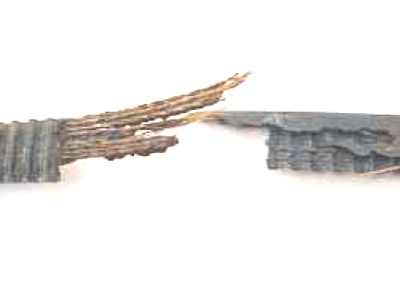

Flexion failure |

| Improper operation, too low installation tension, too small pulley diameter, and foreign matter in the pulley, etc. The rope core of the synchronous belt is arranged in a straight line. | This failure mode occurs when the timing belt is bent to a very small diameter. The sharp bend causes the timing belt core to bend and damage under great pressure. |

Impact load |

| The load exceeds the tension of the synchronous belt, causing the tooth root to crack and/or the tooth to fall off. | Timing belt teeth can develop root cracking and/or tooth shedding after immediate impact load in the timing pulley. |

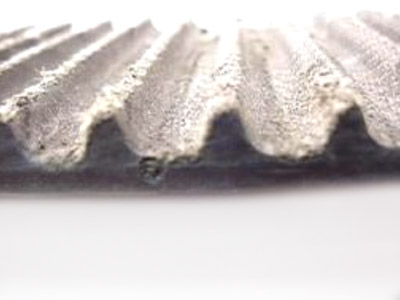

Excessive tension |

| Too high a tension during the installation of the synchronous belt may cause the teeth to shear or break. | Excessive tension surface pressure can cause large areas of wear on the timing belt, exposed core wire and root cracking. |

Tension is too low |

| Usually the timing belt skips teeth or wears teeth due to low tension | Usually, the failure mode of synchronous belt under low tension is manifested as skipping teeth and hook wear. |

Timing pulley is not parallel |

| The timing wheels are not parallel, and the load is uneven, leading to failure | When the synchronous belt is running, the synchronous wheel shaft is at a certain angle. Due to the uneven load applied to the synchronous belt, obvious wear will occur on the side with severe extrusion. |

| Foreign matter has entered |  | Tension wire breaks due to foreign matter | Foreign matter is mixed between the synchronous belt and the synchronous wheel, damaging the belt teeth and rope core, and the rope core usually breaks inside. |

Note: The photos of failure form are from the Internet, which is convenient for analyzing the cause by example

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt