Timing belt installation guide

Timing belt and the timing pulley are used together, and both are indispensable, so when installing the device, the tooth profile of the timing pulley must be matched, so that the installation can be completed normally.

1.Cut off mechanical power.

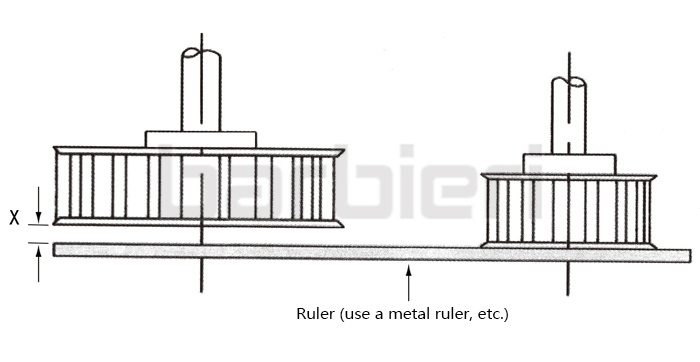

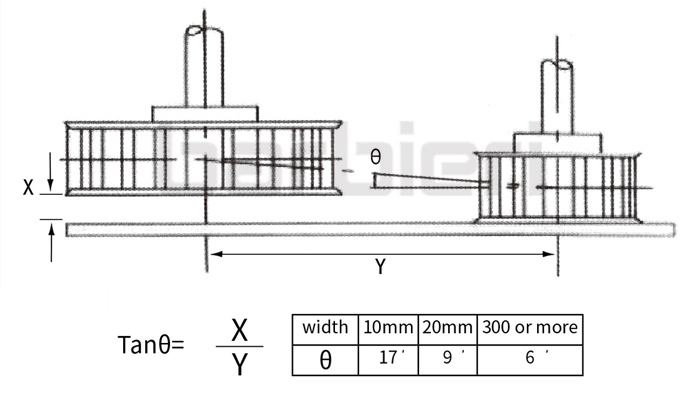

2.Check if they are in the same plane.

Make adjustments so that the X dimension becomes 0 (zero) as much as possible

Hold the ruler against the side of the pulley to confirm that a pair of pulleys are in the same plane.

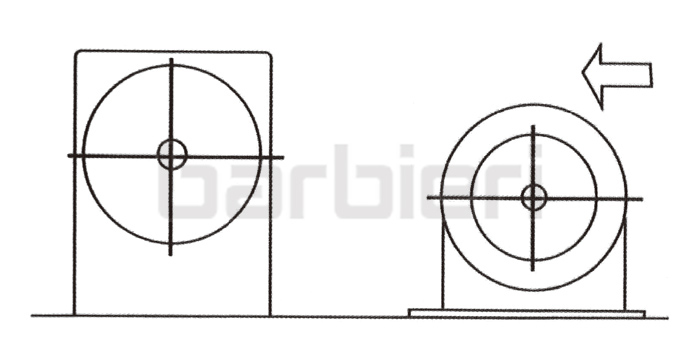

3.Reduce shaft spacing

Loosen the bolts of the sliding base, etc., and shorten the distance between the shafts, so that the belt can be easily installed on the pulley.

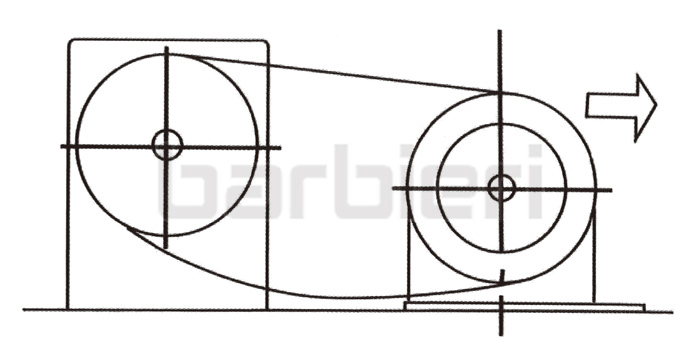

4.Tension the belt.

Align the belt teeth with the tooth grooves of the pulley, and slowly pull the sliding base to tighten the belt.

Since the belt is slightly short when no tension is applied, the belt and pulley may not fully mesh with a pulley with a large number of teeth, so pull slowly to eliminate the part where the belt and pulley are not meshed properly.

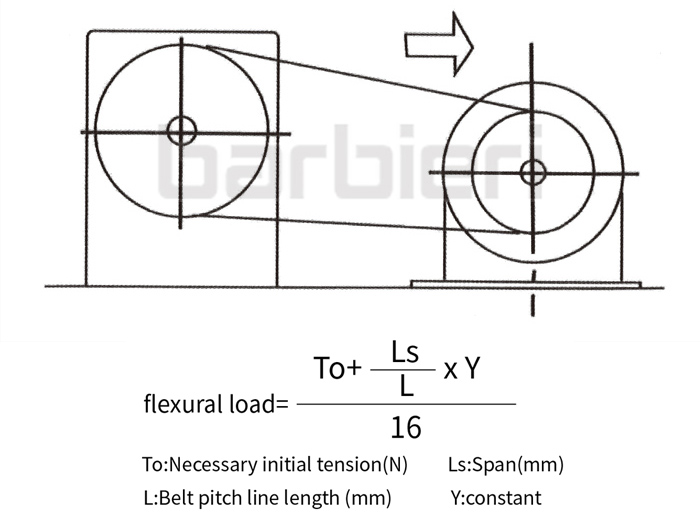

5.Tension the belt to the specified tension

Tension the belt and press at the midpoint of the belt span (the part of the belt not touching the pulley) to create a certain amount of deflection (16/1000 of the span) so that the deflection load at this time is equal to the value obtained by the following formula .

6.Readjust the alignment

With the belt tensioned, check the alignment again with a ruler. If there is any abnormality, remove the belt and adjust it again.

Especially when a single-sided bearing is used, the shaft may be deflected and the belt will deflect to the opposite side of the bearing during operation. In this case, the parallelism of the shaft should be corrected in advance to eliminate the deflection.

7.Securely secure the sliding base so that it does not move.

8.Check engagement

Slowly turn the pulley to check that the belt and pulley mesh accurately.

If the belt does not mesh accurately, check the following:

①Belt is too tight or too loose

②Abnormal outer diameter of pulley (for example, the outer diameter becomes smaller due to wear, etc.)

③The shape of the pulley does not match the shape of the belt.

Timing belt installation precautions

1. When installing the synchronous belt, if the center distance of the two synchronous wheels can be moved, the center distance of the synchronous wheels must be shortened first, and then reset the center distance after the synchronous belt is installed. If there is a tensioning wheel, you can loosen the tensioning wheel slightly, then install the timing belt, and then install the tensioning wheel.

2. When installing the synchronous belt on the synchronous wheel, be careful not to use too much force, and do not use a screwdriver to pry the synchronous belt to prevent damage to the synchronous belt.

3. At the same time, adjust the initial interfacial tension of the synchronous belt to an appropriate level.

4. The frame supporting the synchronous pulley must have sufficient rigidity, otherwise the two axes will not be parallel and the pressure will be uneven when the synchronous pulley is running, which will cause the synchronous belt teeth to wear.

5. In synchronous belt transmission, the parallelism of the axes of the two synchronous pulleys should be appropriate, otherwise the synchronous belt will deviate during operation, and in severe cases, it will jump out of the synchronous pulley.