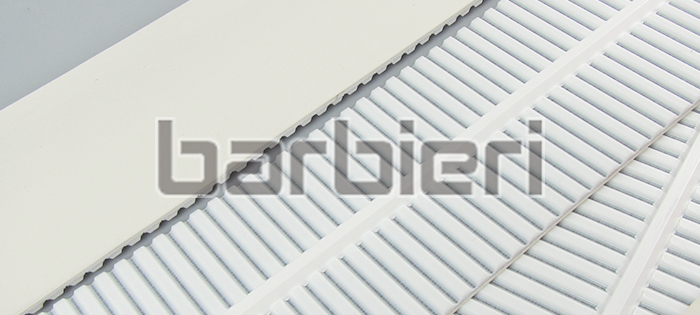

Timing belt with anti-deviation function

Barbieri®The tooth surface of the synchronous belt adding guide bar has the function of positioning and guiding. It makes the synchronous belt run accurately on the equipment and prevent horizontal movement. The guide bar can also be used to position the material on the conveying bearing surface. Welding guide bar needs to be designed to gether with milling teeth. The all-in-one guide bar has transverse grooves. so that the turning radius of the timing belt has the greatest flexibility.

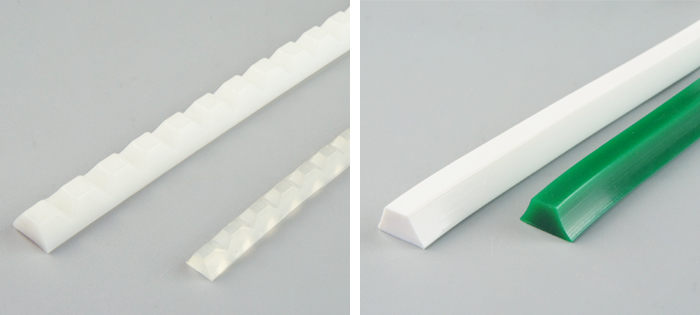

1.Extruded V-Guides

An integrated V-shaped guide, also called an All-in-one guide bar, is extruded during the manufacture of the timing belt.

PU synchronous belt with integrated tracking central guide

2.Welded V-Guides

If a special guide is required that is not available as an extruded V-guide, an alternative is to use a welded V-guide, where the guide bar is welded into the grooves of the milled teeth, also known as a Welded guide bar.

Timing belt with welding PVC tracking central guide

Welded V-guides are available in two different types:

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt