Under what circumstances does the timing belt need a tensioner? And how to tension the timing belt?

Not all timing belt drives need a tensioner. Whether the timing belt needs a tensioner depends on the specific transmission requirements and working conditions. For short-distance, low-load transmissions, the timing belt may not need a tensioner because its tension does not change much and the transmission stability is also high; for long-distance, high-load transmissions, due to the large changes in the belt tension, a tensioner is necessary to ensure high efficiency and stability of the transmission.

Timing belt generally need a tensioner in the following circumstances:

1. Prevent poor meshing: Long-term use will cause the timing belt to loosen, affecting the meshing accuracy and transmission performance. The tensioner can prevent this and ensure the normal operation of the timing belt.

2. Increase the wrap angle to improve transmission efficiency: Appropriate tensioning can adjust the wrap angle and improve transmission efficiency and stability.

3. Too large center distance: If the center distance is too large, it may cause the timing belt to jump. At this time, a tensioner is needed to stabilize the transmission.

4. The center distance is fixed and cannot be adjusted: When the positions of the driving wheel and the driven wheel are fixed and the center distance cannot be adjusted by moving, a tensioner needs to be installed to keep the timing belt taut.

5. Spatial position adjustment: Sometimes it is necessary to change the spatial position of the timing belt, such as avoiding other parts on the transmission path. At this time, the tensioner can help achieve this goal.

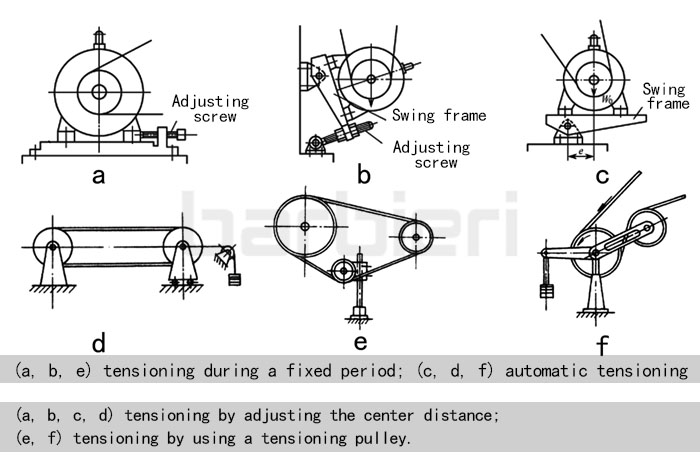

The tensioning methods of the timing belt mainly include the following:

1. Adjust the center distance tensioning

The tension of the timing belt is directly adjusted by changing the center distance between the timing pulley. For example, move the position of the driving wheel or the driven wheel, increase or decrease the distance between the two axes to achieve tension adjustment.

Principle: Use the adjustability of the axis distance to directly change the tension of the timing belt through mechanical structures (such as slide rails, adjustment bolts, etc.).

2. Tensioner tensioning

Add an independent tensioner (idler pulley or timing pulley) to the timing belt drive system, and apply pressure to the timing belt through the wheel to adjust the tension.

Principle: The tensioner is usually installed on the loose side of the timing belt, and uses springs, torsion springs or guide rails to automatically or manually adjust the pressure on the timing belt.

Periodic tensioning: Tensioning is performed by manually adjusting screws, etc. It is suitable for general applications. It has a simple structure and low cost, but requires regular inspection and adjustment, which may affect the continuous operation of the equipment. Automatic tensioning: Automatic tensioning uses a special tensioning mechanism to automatically adjust the tension of the timing belt according to the working state of the timing belt. It is suitable for high-intensity, long-term continuous working occasions. It can keep the timing belt in a good tension state in real time to ensure its stability and service life, but the cost is high.