What are the commonly used materials for timing pulleys and what are the characteristics of timing pulleys of different materials?

When selecting the material of the timing pulley, it is necessary to select the appropriate material according to the working environment, transmission requirements and other factors to ensure the normal operation and working efficiency of the transmission system. It should be comprehensively considered according to the specific situation and follow the rules of material selection to obtain the best use effect.

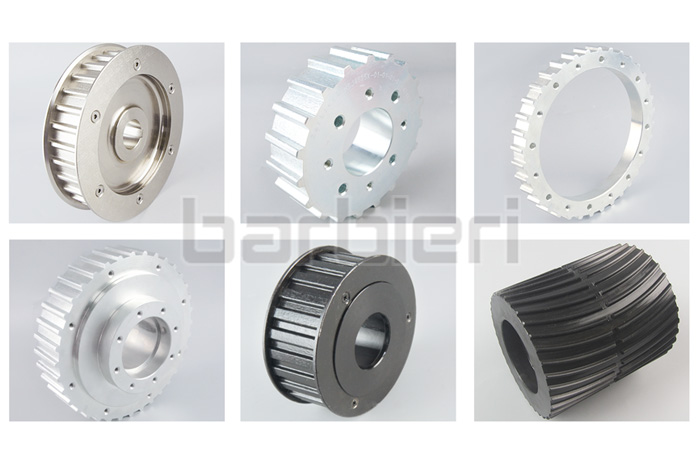

Common timing pulley materials include: aluminum alloy, 45# steel, cast iron, plastic, etc.

1. Aluminum alloy timing pulley (7075, 6061, 6063, 2A11, LY12, AL, etc.)

The timing pulley made of aluminum alloy has the characteristics of light material, low density, good thermal stability and wear resistance, which can reduce the weight of the whole machine and improve the operation efficiency of the machine. It is usually used in high-precision and high-speed mechanical equipment such as robots and CNC machine tools.

2.45# steel timing pulley (Q235, S45C, C.R.S, ordinary carbon steel, etc.)

45# steel timing pulley has good strength and wear resistance. Its strength and hardness are higher than aluminum alloy synchronous pulleys, and it has higher durability and service life. However, the weight of the wheel body is relatively heavy. It is usually used in industrial machinery and vehicle transmission systems, high-load and high-speed transmission mechanical equipment.

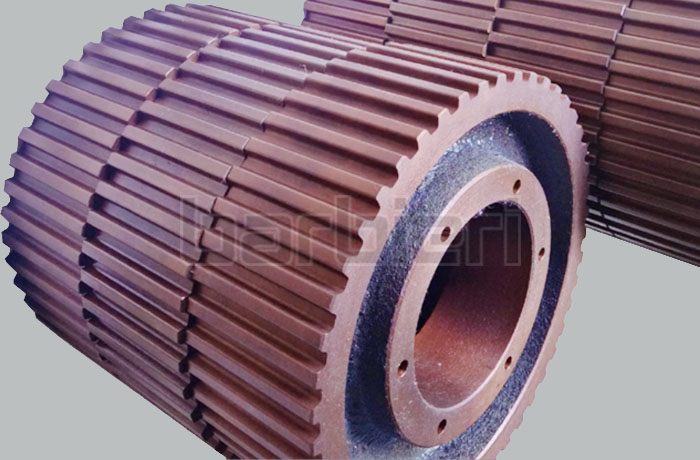

3. Cast iron timing pulley (HT150, HT200, HT250, etc.)

Cast iron timing pulley is a timing pulley made of cast iron (pig iron) material. It has the characteristics of high temperature resistance and is often used for large diameter pulleys. The production cost is relatively low, but cast iron synchronous pulleys are prone to noise and vibration, and the relatively fast wear speed and short service life are usually used in engineering machinery, mining, harsh working environment, heavy-duty transmission power, high speed and heavy-duty industries.

4. Plastic timing pulleys (POM, nylon, etc.)

Plastic timing pulleys are corrosion-resistant and suitable for use in humid environments or underwater work. They are suitable for use on low-load, low-speed machines and are often used in industries such as furniture, toys, and office equipment.

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt