What are the processing methods of PU timing belt

Polyurethane timing belt is also PU timing belt, which is made of thermoplastic polyurethane material. It has the characteristics of wear resistance, tensile strength and good stability. There are many models. According to different classifications, there are AT type, T type and HTD type , RPP type, STD type, and other models. The synchronous belt is a common mechanized equipment component. Although it is inconspicuous, it has a great effect. If it is missing, the machine cannot operate. timing belt are used in a wide range of industries, and the timing belt used by different machines are also different, and some require special processing and customization of timing belt.

What are the ways of timing belt processing?

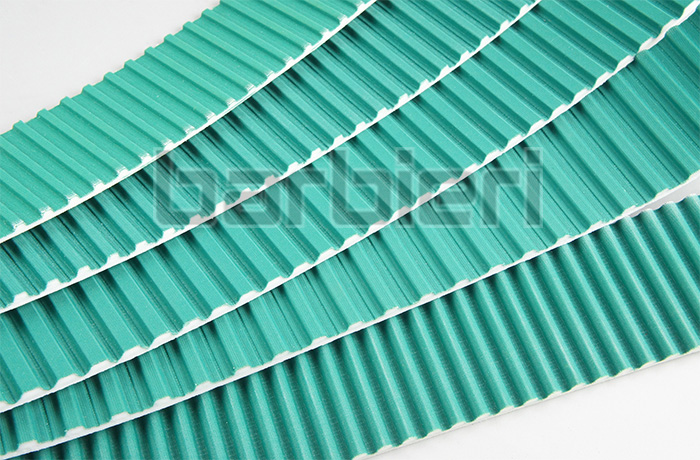

The characteristics of the covered timing belt : increase the friction and reduce the hardness of the material, so that the goods can be transported more smoothly on the synchronous belt, and at the same time have the properties of anti-cracking, wear-resistant, anti-aging and so on.

(Our company can choose from customers: PU, PVC, APL, EVA, rubber, silicone, sponge, felt, and other patterned surface coverings)

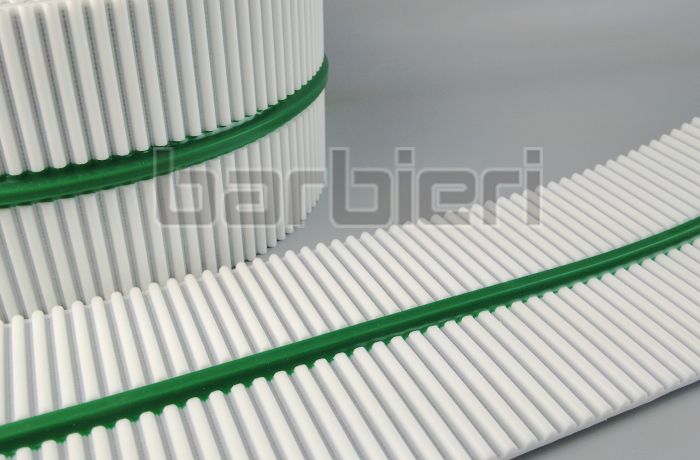

2. Timing belt with green cloth

With green cloth timing belt features:The cloth on the tooth surface can reduce noise; the cloth on the back can increase friction and prevent slipping.

(Our company can choose from customers: green cloth/white cloth/black cloth)

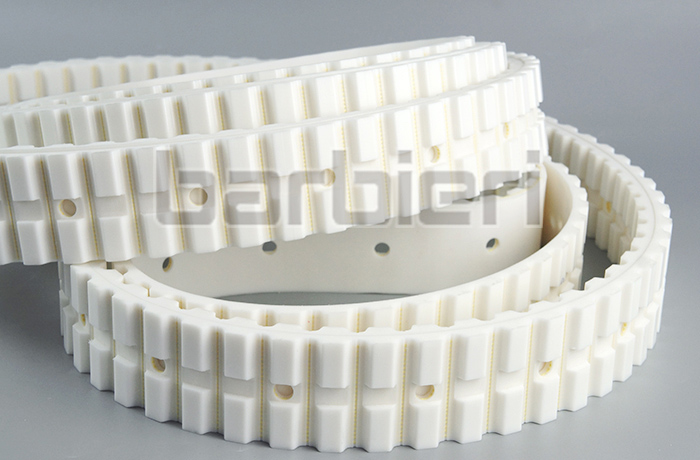

Features of timing belt with guide strips: Adding guide strips on the tooth surface of polyurethane timing belt can make the timing belt highly consistent with the gear and make it run more precisely. At the same time, it has low elongation, flexibility and strong load capacity. Solve the problem of belt deviation.

(Our company can choose from customers: integrated guide strip timing belt or welded guide strip timing belt)

Welding guide bar timing belt

Timing belt with integrated tracking central guide

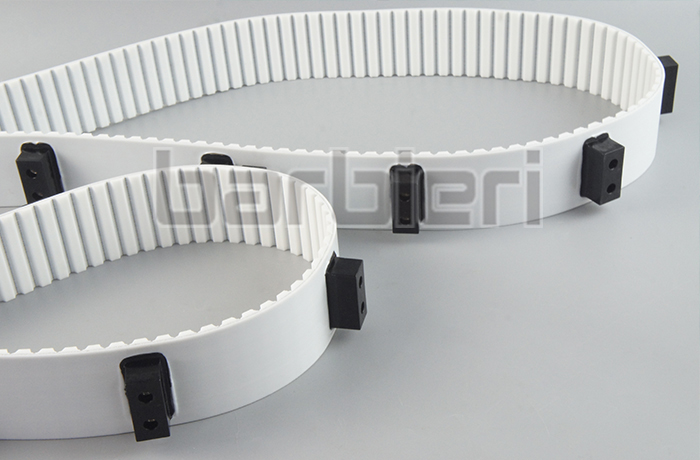

The characteristics of the cleats timing belt : it is mainly used for single timing belt transmission, multiple timing belt transmission, precise positioning transmission, the timing belt needs to be installed with fixtures, and needs to be screwed on the timing belt baffle.(Specialprocessing customers need to provide drawings)

5. Timing belt punching, tooth milling, slotting, horizontal groove, longitudinal groove.

Its features: it is used for air suction, so that the products conveyed on it can be close to the surface of the conveying belt, so that the conveying can be carried out normally and orderly; install accessories, install other parts on the belt; use for product positioning, etc.

( Special processing customers need to provide drawings)

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt