What is the basic principle of timing belt drive& What are the advantages of timing belts?

The basic principle of timing belt drive

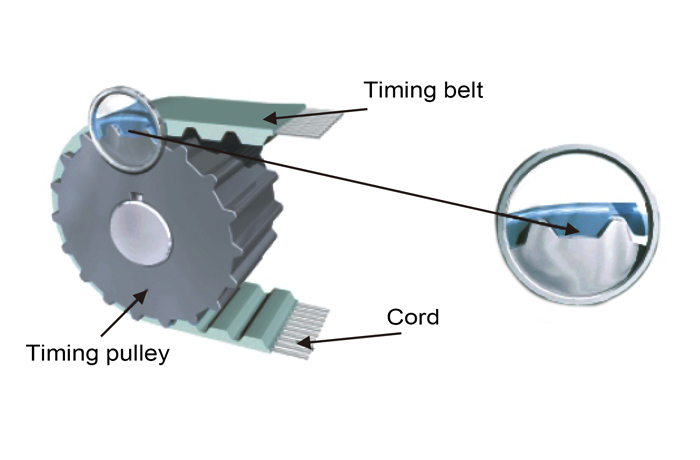

Timing belt drive transmits motion by the meshing of the teeth on the timing belt with the corresponding cogs on the timing pulley. Compared with the friction belt drive, there is no relative slip between the synchronous wheel and the synchronous belt of the synchronous belt drive, which can ensure a strict transmission ratio, but the synchronous belt drive has higher requirements for center distance and dimensional stability.

Timing belt advantages

1. Accurate rotation ratio

The timing belt drive is a kind of meshing transmission, the transmission ratio i=Z2/Z1, although the base of the timing belt is polyurethane or neoprene rubber, which is elastic, but the strength layer bearing the load is made of steel wire and glass fiber material with a small elongation Die-casting, the elongation is extremely small under the action of working tension and variable stress, and the pitch of the synchronous belt remains unchanged, so that the belt teeth and the synchronous wheel tooth grooves are correctly meshed, no steps are lost, and synchronous transmission without slippage is realized, and accurate The transmission ratio is high, the transmission efficiency is as high as 98%, and the transmission is stable, and it has the function of buffering and vibration reduction.

2. Compact structure

The working force borne by the synchronous belt transmission is the force transmitted by the tooth side meshing. Compared with the V-belt pulley that only relies on friction to transmit motion and power, the diameter of the synchronous pulley is much smaller and does not require a large tension force. , The drive shaft force received by the synchronous wheel shaft is reduced, so that the diameters of the synchronous wheel shaft and the rolling bearing can be reduced, so the synchronous belt drive has a more compact structure.

3. Adapt to harsh working conditions

In harsh working conditions with corrosive media and water leakage, the chain is prone to rust, wear, and corrosion; the V-belt drive will slip due to the reduced friction coefficient; but the synchronous belt drive is a meshing drive and does not slip.

When there is dust and impurities, when the teeth of the synchronous belt enter the groove of the synchronous wheel, the teeth will squeeze the air in the groove of the synchronous wheel, so that the squeezed air will be discharged to both sides of the groove. The pressure will take away the dust and impurities, clean the meshing surface, and reduce the friction loss of the synchronous belt.

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt