What material is the timing belt made of

The common timing belt has two materials: one is rubber timing belt, the other is PU timing belt

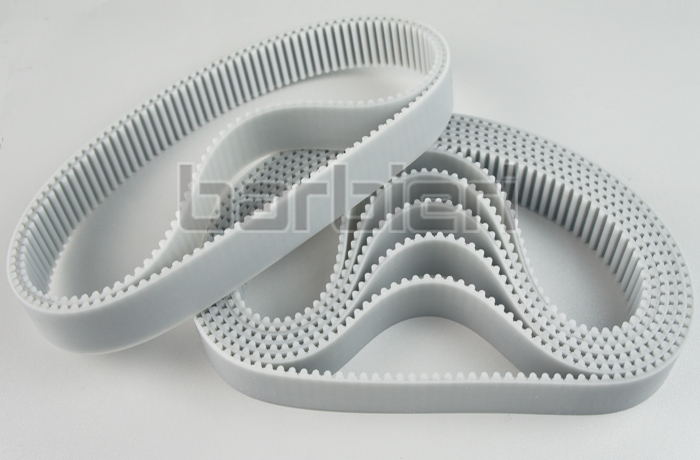

The PU timing belt generally consists of a galvanized steel wire core (or stainless steel wire core or Kevlar core) as the strength layer, which is covered with polyurethane. Divided into thermoplastic polyurethane (TPU timing belt); thermosetting cast polyurethane (CPU timing belt).

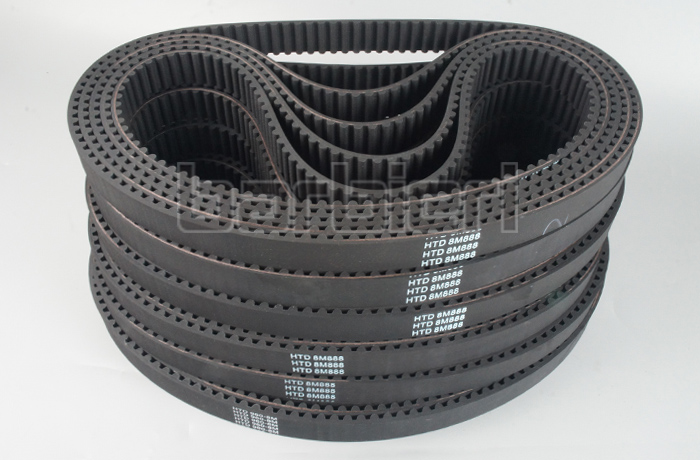

The rubber timing belt is made of neoprene as the main raw material, mixed with a variety of auxiliary materials for different purposes, the skeleton material is glass fiber cord, and the tooth surface is protected by nylon high elastic cloth.

1. PU (CPU) timing belt is made by mold casting. This type of timing belt product has accurate size and is used in various transmission occasions such as oil resistance, water resistance and solvent resistance. Mold specifications are not as complete as rubber products; and the post-processing performance is poor, and processing such as baffles cannot be added; therefore, most of this type of products are limited to relatively fine transmission occasions or various power tool occasions.

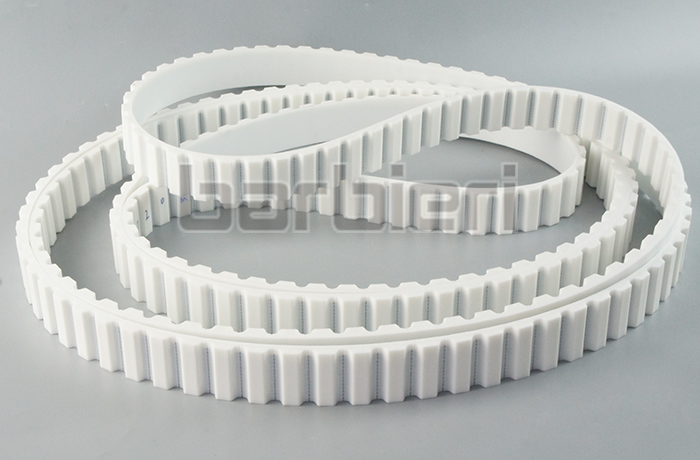

2. PU (TPU) open timing belt adopts the production process of cable extrusion molding. The length can theoretically be unlimited, so any length specification can be produced. Barge ring belt), thermoplastic performance is good, easy to interface, oil resistance, solvent resistance, waterproof, sanitation and other performances are good, all kinds of coverings are relatively firm in post-processing, and are often used in various long-distance synchronous transmission occasions, or for open belts It is used in linear reciprocating motion transmission occasions.

3.PU (TPU) Truly endless timing belt adopts winding extrusion molding production process. This type of product can be produced in any specification within a certain length range. The product is wear-resistant, oil-resistant, waterproof, solvent-resistant, hygienic, High tensile strength, good post-processing performance, etc., can be used in any occasions such as transmission or transportation. These products are non-standard customization, the delivery time is long and the price is slightly expensive.

4.The rubber timing belt adopts the mold fluidization production process. This kind of product has a wide range of uses and is used in various transmission occasions. Due to the poor oil resistance, water resistance and solvent resistance of rubber timing leather products, and it is not suitable for direct contact with food, coupled with the limitation of mold specifications, it is impossible to customize any specification according to customer needs.

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt