timing belt

-

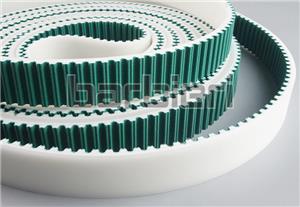

STD8M-PAZ Timing Belt With PU anti-skid patter

Barbieri® STD8M-PAZ Timing Belt With PU anti-skid patter : Made of thermoplastic polyurethane, embedded with high-strength steel wire core, high quality, high wear resistance, smooth operation under high load, tooth surface plus PAZ, reduce friction coefficient, reducing noise and improving tooth engagement. Transport wear-resistant parts are often used in conveyor lines in the woodworking industry, with high wear resistance, strong tensile strength and durability.

Woodworking conveyor line timing belt Jacking transfer machine timing belt lifting transfer machine timing beltEmail Details -

H Timing Belt With White Rubber Coating

Barbieri® H timing belt white rubber: H-tooth timing belt is made of thermoplastic polyurethane with a high-strength steel wire core embedded inside. It can withstand large loads and is suitable for various mechanical equipment that require high load-bearing capacity. Adding white natural rubber on the back of the timing belt can further improve the wear resistance of the back, while increasing the buffering and shock absorption capabilities.

White rubber timing belt White rubber coating timing belt White rubber coated PU timing belt H timing belt white rubberEmail Details -

HTD8M Timing Belt With Black Natural Rubber Coating

Barbieri® HTD8M Timing Belt With Black Natural Rubber Coating: Made of thermoplastic polyurethane with embedded high-strength steel wire core, high quality and high wear resistance. General transportation, commonly used in woodworking machinery, glass transportation, transportation wear-resistant, strong tensile strength and other characteristics.

Black rubber coating timing belt Rubber coating timing belt Natural rubber coated timing belt Black natural rubber PU timing beltEmail Details -

H、XH Timing Belts With White PU Coating

Barbieri® H, XH Timing Belts With White PU Coating: Made of thermoplastic polyurethane with embedded high-strength steel wire core, high quality, high wear resistance and smooth operation under high load. Commonly used in Glass edging machine timing belt, oil-proof and grease-proof, high wear resistance, strong tensile strength and durable.

Glass edging machine timing belt Glass straight line edging machine timing belt Timing belt with pu coating Timing belt for glass edging machineEmail Details -

Stainless Steel Core Timing Belt With PU Covering

Barbieri® Stainless steel wire timing belts are made of thermoplastic polyurethane with a stainless steel wire core embedded inside. They have high corrosion resistance and can withstand harsh environments and high loads.

Timing belt with stainless steel wire AT20 Stainless steel core timing belt AT10 Stainless steel core timing beltEmail Details -

PU timing belt RPP8M-PAZ

Barbieri® RPP8M-PAZ+PU toothed belt has a pitch of 8mm and is commonly used in glass cutting machine timing belts to provide stable and reliable cutting performance for glass cutting machines. RPP8M tooth shape has a special double-peak tooth shape, also known as rabbit tooth synchronous belt. The force is dispersed to two tooth peaks, the force is more uniform, the turning effect is good, and it is suitable for high-speed transmission characteristics.

Glass cutting machine timing belt Modified arc tooth profile RPP8M RPP8M timing belt RPP8M Glass Cutting Machine Timing BeltEmail Details -

High Temperature Resistant Felt Synchronous Belt

Barbieri® High temperature resistant felt synchronous belt: made of thermoplastic polyurethane, embedded with high-strength steel wire core, good quality, high wear resistance, and can run smoothly under high load. The gray felt timing belt is resistant to high temperature and abrasion. It is often used in transportation where the surface of the object needs to be protected. It can effectively prevent the object from slipping and deforming, which greatly improves the grade and quality of the product.

Email Details -

High Temperature Kevlar Felt Timing Belt

Barbieri® Kevlar felt timing belt : Made of thermoplastic polyurethane, embedded with a high-strength steel wire core, high quality, high wear resistance, and can run smoothly under high loads. The heat-resistant felt timing belt is widely used in aluminum profile high-temperature conveying production lines, which can effectively prevent aluminum profiles from slipping, not bumping and deforming, and greatly improving the grade and quality of products.

Heat insulation felt timing belt Kevlar felt timing belt Heat resistant timing belt Aluminum heat-resistant timing beltEmail Details -

Polyamide nylon fabric antistatic belt

Barbieri® Antistatic timing belt: Made of thermoplastic polyurethane, with a high-strength steel wire core embedded inside, and the polyamide nylon fabric on the tooth surface and back is antistatic.

Antistatic timing belt Black fabric antistatic timing belt PU timing belt antistatic Anti-static timing beltEmail Details