Black Bagged Spring Production Line Timing Belt With Nut Profiles

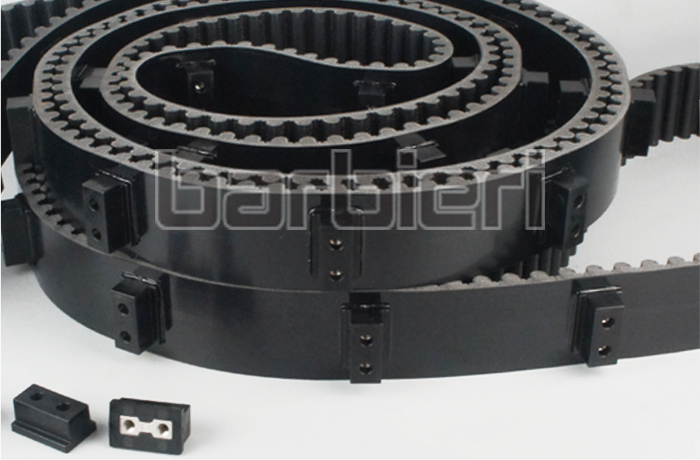

Barbieri® Timing belt with nut profiles It is made of thermoplastic polyurethane, with a steel wire rope core inside, and a nut stopper is welded on the back of the black timing belt.

It is often used in pocket spring production line equipment. The stainless steel nut in the stopper perfectly cooperates with pocket spring production equipment to provide accurate positioning and conveying, which greatly improves production efficiency.

The nut stopper adopts welding stopper processing equipment, and the stopper is welded on the back of the timing belt according to the required spacing. The connection between the timing belt and the baffle block is very firm.

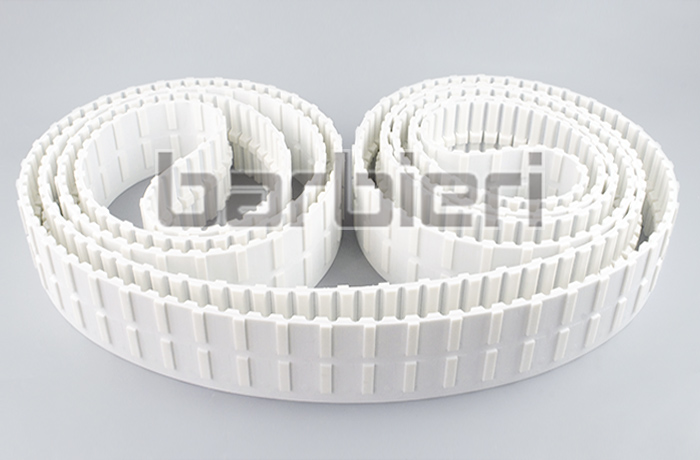

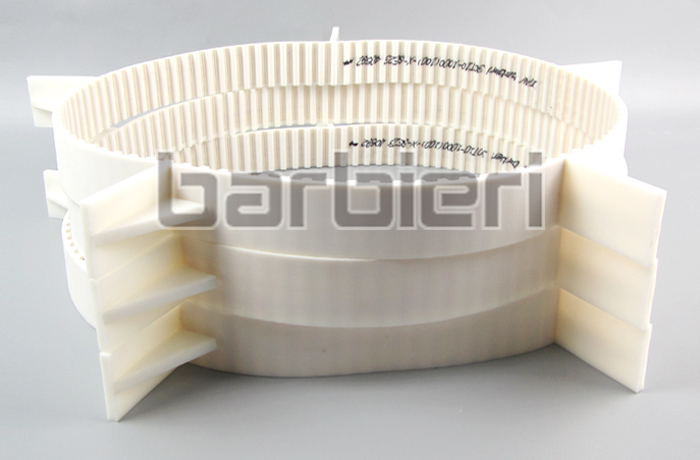

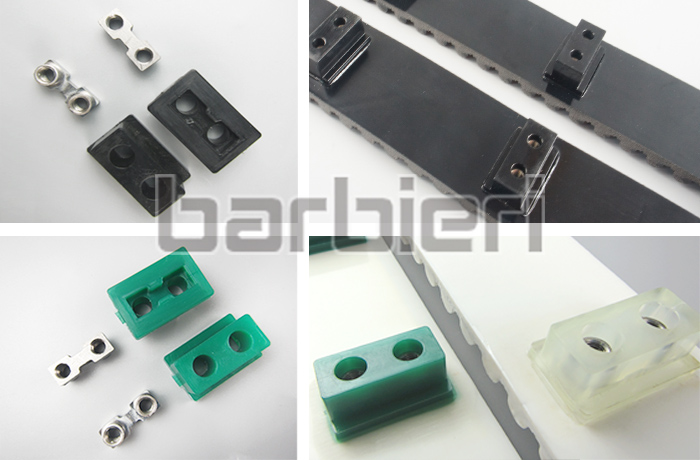

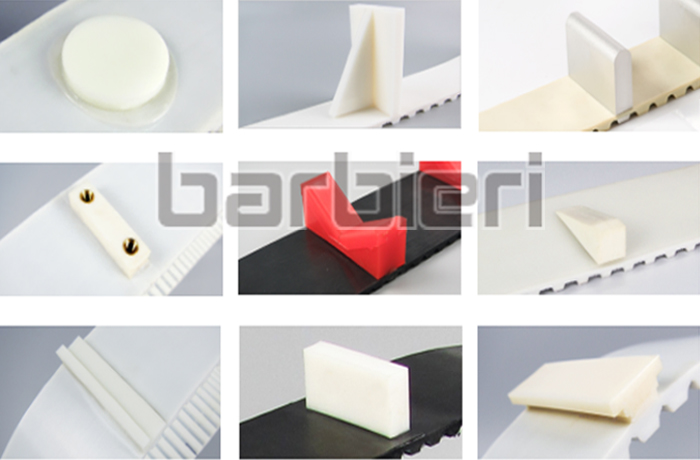

White timing belts or black timing belts with different tooth shapes can be customized according to customer requirements, and nut blocks of different colors can also be selected.

Barbieri®-J and Barbieri®-flex polyurethane timing belts can be designed with stoppers to meet applications in transportation, handling and positioning. The stopper is made of the same material as the timing belt to ensure maximum strength. Timing belts with stoppers can synchronize products with high speed and low noise.

We provide many kinds of stoppers for customers to choose from, and can develop timing belts with special-shaped stoppers. If the stopper you need is not listed, please contact us.

Barbieri® polyurethane belt having a highly wear-resistant, dimensionally stable, good welding characteristics, special specifications for welding stopper is used to meet a variety of production needs of the industry.

1.Single synchronous belt conveying: customize the size and spacing of the stopper according to the size and shape of the conveyed product, and install the stopper on a single synchronous belt for conveying;

2. Simultaneous conveyance of multiple synchronous belts: customize the size and spacing of the stoppers according to the size and shape of the conveyed product, and install stoppers on multiple synchronous belts for synchronous conveying;

3. Accurate positioning and transmission: When the equipment needs to be sensed at a certain distance, install the stopper according to this distance to achieve accurate sensing effect, such as the conveyor belt of the inkjet printer;

4. Timing belt stopper installed with screws: a stopper with single or multiple nuts can be welded on the back of the timing belt, the nuts will not fall, and the positioning is accurate;

5. Special purpose is needed when the machine is used: various kinds of special stoppers can be developed and produced according to the design requirements of customers.