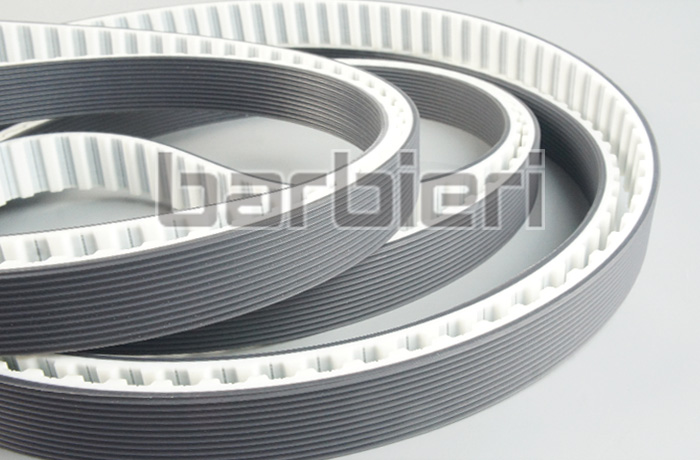

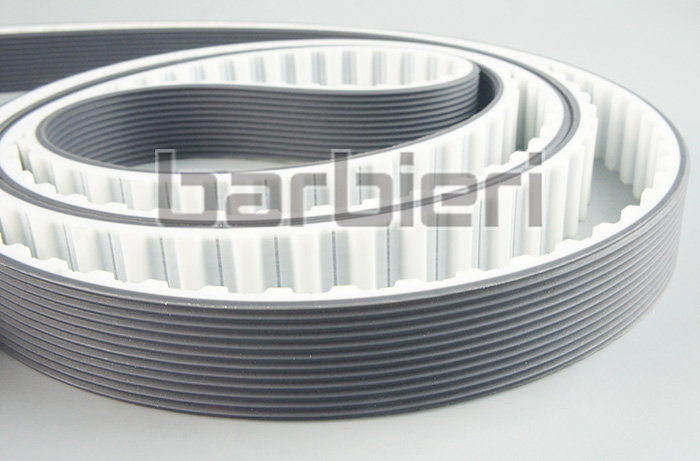

AT10 H Timing Belt with Straight Stripe Coating

Barbieri®AT10 H Timing Belt with Straight Stripe Coating: Manufactured from thermoplastic polyurethane with embedded high-strength steel wire core, it is of high quality, has high abrasion resistance, and runs smoothly under high loads.

Transport wear parts are often used in glass conveying or woodworking conveying lines, with high wear resistance, strong tensile strength and durability.

Longitudinal groove timing belt can be customized with different tooth shape, length and width according to customer requirements.

Grey Longitudinal line timing belt: commonly used in conveyor lines in the glass industry, with a surface rubber hardness of 85°Shor A

Transparent Longitudinal line timing belt: commonly used in conveyor lines in woodworking industry, surface rubber hardness 65°Shor A

Timing belt tooth surface plus PAZ, reduce friction coefficient, reduce noise and improve belt tooth meshing.

Our production belt models include:

STD3M,STD5M,STD8M,STD14M,AT5,AT10,AT20,T5,T10,T20,XL,L,H,XH,HTD3M,HTD5M,HTD8M,HTD14M,RPP5M,RPP8M,RPP14M,P1,P2,P3,P4,TT5,TK10-6,

TK10-K13,ATK10-K13,And other special belt.

Mechanical properties:

● Dimensional stability, low pre-tension, low axial load

● High abrasion resistance, good elasticity, maintenance-free

● Lower noise, high efficiency, high precision for line and angle location

Chemical Properties:

● Well-resistance to hydrolysis , ozone, UV and anti-aging

● Well-resistance to oil and grease

● Well corrosive resistance to most of acids and alkali

● Normal working temperature -10℃ to +60℃ (+80℃ is affordable in n a short time)