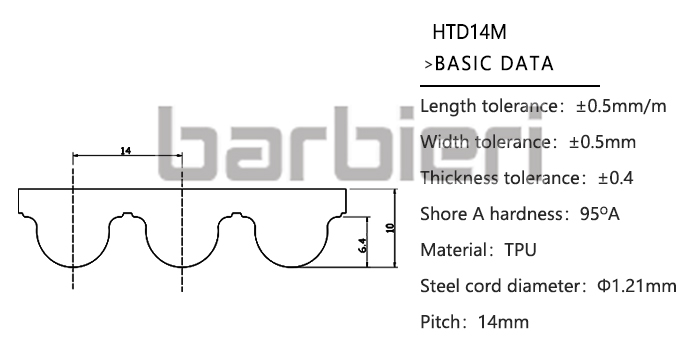

HTD Toothed Industrial Circle-arc Tooth Timing Belt

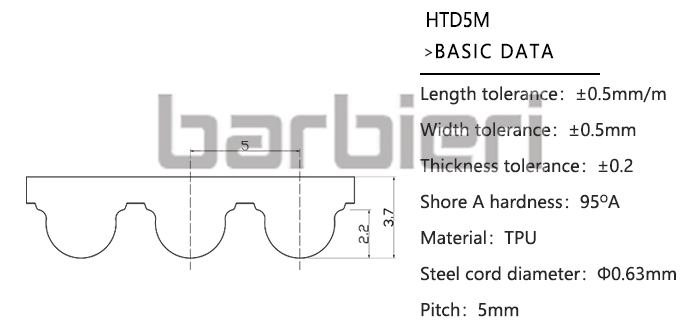

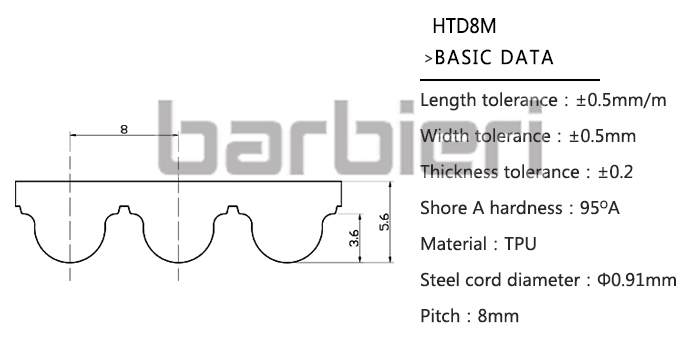

Barbieri® HTD toothed timing belt: made of thermoplastic polyurethane, embedded with high-strength steel wire core, high quality, high wear resistance, and can run smoothly under high load.

Polyamide cloth can be added to the back and tooth surfaces as required to reduce friction coefficient, reduce noise and improve belt tooth meshing.

HTD toothed timing belt:Full arc tooth belt transmission precision, low noise characteristics.

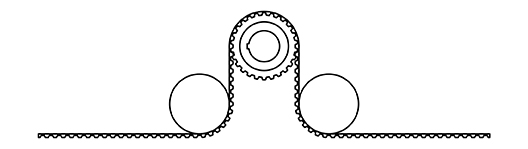

| Drive without reverse bending | Min. teeth No. of pulley A | 16 |

| Min. diameter of idler B | 30mm | ||

| Drive with reverse bending | Min. teeth No. of pulley C | 25 |

| Min. diameter of idler D | 60mm | ||

| * A:drive pulley,B:idler on teeth,C:drive pulley,D:idler on back | |||

| Drive without reverse bending | Min. teeth No. of pulley A | 18 |

| Min. diameter of idler B | 50mm | ||

| Drive with reverse bending | Min. teeth No. of pulley C | 30 |

| Min. diameter of idler D | 120mm | ||

| * A:drive pulley,B:idler on teeth,C:drive pulley,D:idler on back | |||

| Drive without reverse bending | Min. teeth No. of pulley A | 28 |

| Min. diameter of idler B | 120mm | ||

| Drive with reverse bending | Min. teeth No. of pulley C | 28 |

| Min. diameter of idler D | 180mm | ||

| * A:drive pulley,B:idler on teeth,C:drive pulley,D:idler on back | |||

Mechanical properties:

● Dimensional stability, low pre-tension, low axial load

● High abrasion resistance, good elasticity, maintenance-free

● Lower noise, high efficiency, high precision for line and angle location

Chemical Properties:

● Well-resistance to hydrolysis , ozone, UV and anti-aging

● Well-resistance to oil and grease

● Well corrosive resistance to most of acids and alkali

● Normal working temperature -10℃ to +60℃ (+80℃ is affordable in n a short time)