Glass laser drilling machine timing belt application case

Glass is a fragile product, which brings many problems to processing, such as cracks, brittleness, scratches, etc., which will seriously

consume too much material and waste labor time. In recent years, with the continuous advancement of technology, ,The emergence

of laser has brought new processing methods to glass processing. Under the control of laser control system, glass laser drilling

technology has the advantages of high precision, high efficiency and low cost, and has become one of the key technologies in the

modern manufacturing field.

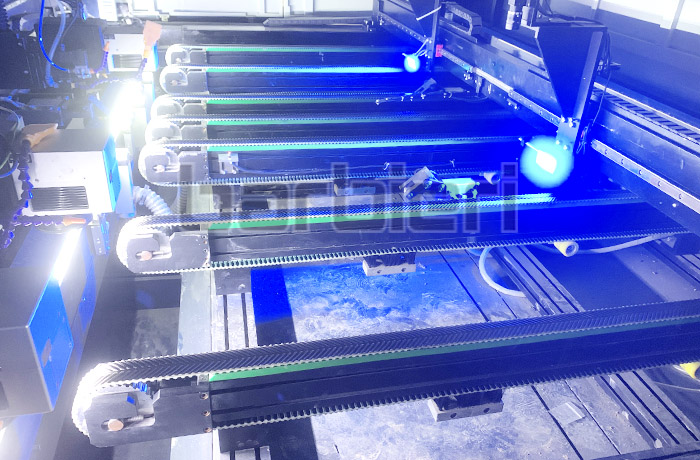

Glass laser drilling equipment usually uses timing belt conveying during the process of loading glass sheets. Multiple timing belts

are required to convey and position the glass side by side.

Glass laser drilling machine timing belt TK10-K13-PAZ7+3.2P2HN produced by barbieri is widely used.

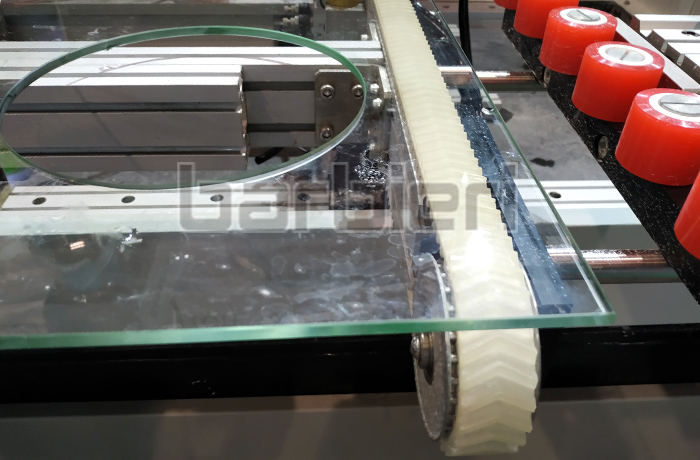

TK10-K13-PAZ7+3.2P2HN integrated guide timing belt, made of thermoplastic polyurethane, with high-strength steel wire core

embedded inside, gray PVC herringbone pattern on the back of the timing belt, green cloth on the tooth surface to effectively

reduce noise, timing belt teeth Adding guide bars on the surface can make the synchronous belt and the gear highly consistent,

making its operation more stable and accurate.

HTD8M+5U0GN Glass laser drilling machine timing belt, made of thermoplastic polyurethane, with a high-strength steel

wire core embedded inside, and a white PU herringbone pattern on the back of the timing belt, which has strong tensile

strength, high wear resistance, durability, and dimensional stability Characteristics such as this can effectively improve

processing performance during production operations, greatly improve work efficiency, and improve the overall quality

of products.

If you need to order, or other different tooth types, lengths, widths, or special customization, please contact our sales manager.