Application cases of timing belt of glass linear edging machine and timing belt of linear beveling machine

Glass linear edge grinding machine and glass linear beveling machine are extremely important in glass processing technology, and are necessary glass processing equipment for glass deep processing. Everyone knows that in the glass edging machine, the grinding head motor and the grinding wheel mainly play a role. It is their existence that realizes the value of this machine. Of course, you should not ignore the timing belt, which is a very important part of the transmission system of the glass edging machine. The quality of the timing belt of the glass edging machine determines the processing accuracy of the glass edging machine.

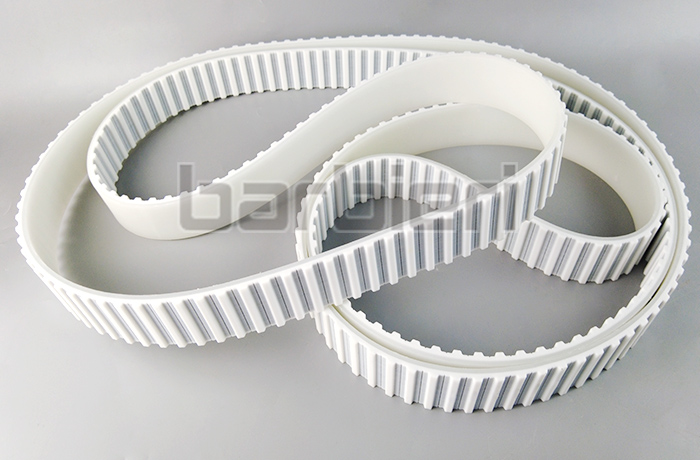

Timing belt of the glass edging machine consists of an endless belt with equidistant teeth on the inner peripheral surface. When rotating, the timing belt teeth are meshed with the pulley teeth and transmitted. The synchronous belt drive for transmission has the characteristics of accurate transmission ratio, no slip, stable transmission, vibration absorption and low noise.

Barbieri® has been cooperating with customers in the glass industry for a long time, and now lists some common models of timing belts for glass linear edge grinding machines and glass linear beveling machine timing belts that are very popular among users: H+PU; XH+PU; T20+PU; AT20 +PU

The timing belt is made of thermoplastic polyurethane, with a high-strength steel wire core embedded inside, and the back of the timing belt is made of abrasion-resistant PU, which has strong pulling force and is not easy to break. The white PU material on the surface is non-slip and wear-resistant, so as to ensure the characteristics during operation and withstand high loads.

If you need to order, according to specific requirements: length, width, tooth type, PU thickness, or other special customization, please contact our sales manager.