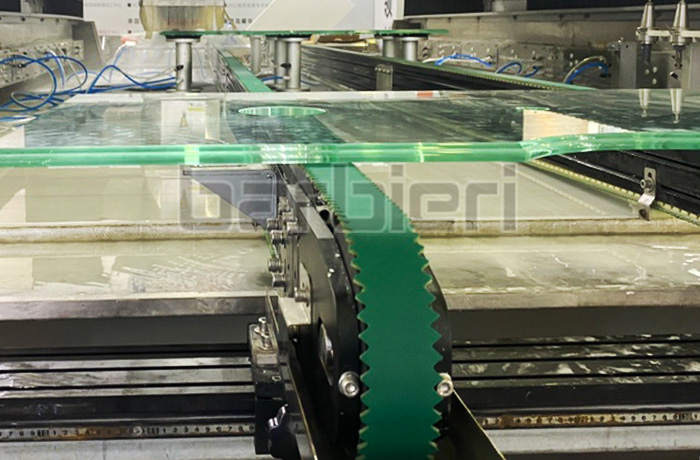

Timing belt application case of glass processing center

CNC glass processing center is a kind of glass machinery equipment. It adopts computer-aided design system and is widely used in glass and mirror special-shaped edging, cutting, lettering, punching, and polishing. It is fully controlled by computer from pattern design and product processing. Intelligent The transmission in the form of assembly line reduces the waste of time caused by manual work, greatly improves work efficiency and yield, and solves the problem of long processing time for loose orders and special-shaped products in the glass industry. Integrated, accurate and fast operation, CNC glass processing center realizes automatic transmission , Automatic positioning, saving time-consuming manual positioning, greatly improving work efficiency.

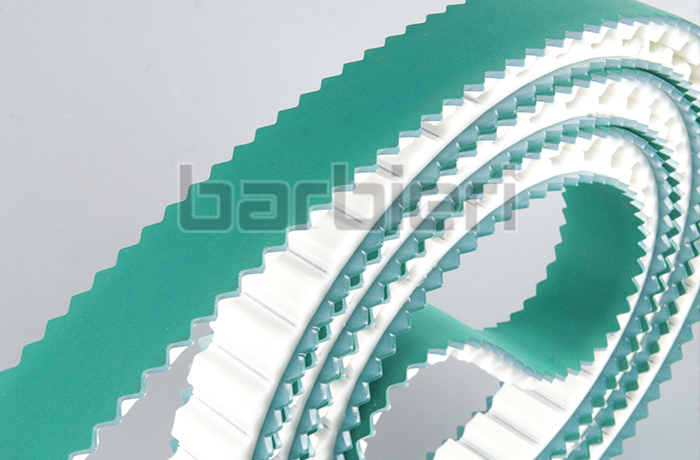

Barbieri® provides customers withCNC glass working center machine timing belt: 30AT20+3PU-PAZ7 is made of thermoplastic polyurethane, embedded with high-strength steel wire core, and the back of the timing belt is added with abrasion-resistant PU and green fine cloth, which is suitable for the transportation of glass products Effective protection and positioning.

The timing belt is specially processed, and the timing belt cover is treated with corresponding tooth shape and tooth edge, which plays the role of accurate positioning when conveying glass. The green cloth on the back is non-slip and anti-grease, which protects the glass without leaving traces. It is a very good choice for glass transportation.

If you need to order, or other different tooth types, lengths, widths, and special customizations, please contact our sales manager.