Causes and treatments for heating of timing pulley

During operation the timing pulley will generate a certain amount of heat due to friction, load and other factors. This heat is normal and inevitable to a certain extent. This does not mean that this phenomenon can be ignored. The heating of the synchronous pulley will reduce the working efficiency of the machine and accelerate the aging of the timing pulley and timing belt, which will not only affect its service life, but may also cause damage to the entire transmission system. Therefore, it is very important to understand the causes of heating of the timing pulley and take measures to deal with it.

Common causes of heating of Timing pulley:

1. Motor mismatch: When the motor equipped with the timing pulley does not match the actual working conditions, the motor will bear too much load during operation, causing heating.

2. The packing gland is too tight: If the packing gland of the synchronous pulley is adjusted too tight, it will increase the friction resistance, increase the motor load, and then cause heating.

3. The mechanical seal spring is too tight: The mechanical seal spring is too tight, which will also increase the friction resistance of the timing pulley, resulting in an increase in the motor load and aggravated heating.

4. Wheel-axle connection problem: If there is a gap between the connection between the timing pulley and the shaft, it will cause vibration and friction, which will increase the motor load and cause heating.

Take the following measures:

1. Motor matching: According to the actual working conditions of the timing pulley, select a matching motor to ensure that the motor has a moderate load during normal operation and reduce heating.

2. Packing gland adjustment: Regularly check and adjust the tightness of the packing gland to ensure that it is within the normal range to avoid increased friction resistance caused by overtightening.

3. Mechanical seal spring adjustment: For mechanical seal springs, appropriate adjustments should be made according to actual conditions to avoid increased friction resistance caused by overtightening.

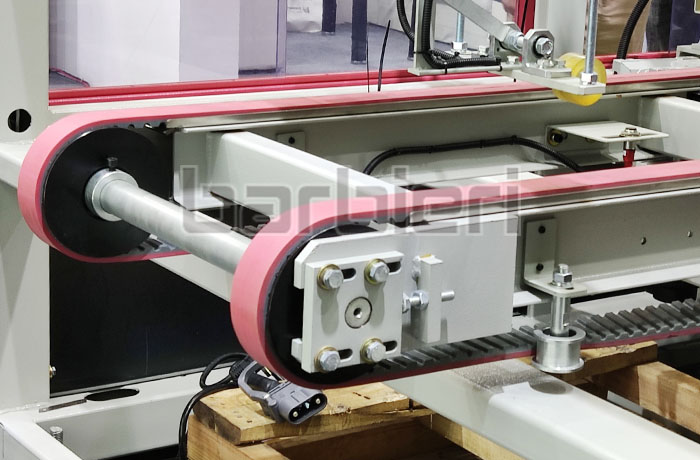

4. Wheel-axle connection inspection: Regularly check the connection between the synchronous pulley and the shaft to ensure that the connection is firm and there is no gap to avoid increased load caused by vibration and friction.

5. Timely shutdown processing: Once the synchronous pulley is found to be heating, it should be stopped immediately for inspection to avoid further damage to the equipment due to long-term operation.

6. Regular maintenance: Regularly maintain the synchronous pulley and transmission system to ensure that the equipment is in good operating condition and reduce the possibility of failure.

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

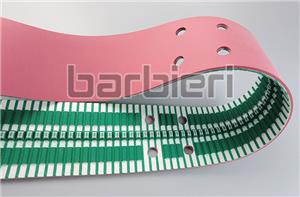

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt