When the timing belt is equipped with a flanged timing pulley, the timing pulley flange design considerations

Timing pulley flange can effectively prevent the timing belt from deviating or falling off during high-speed transmission, thereby ensuring the continuity and stability of the transmission system. In a complex mechanical operation environment, the timing belt may deviate from the predetermined track due to various factors. The presence of the flange can effectively prevent this from happening and ensure the accuracy and reliability of the transmission. The following points should be noted:

1. The width of the timing pulley flange is generally recommended to be about 2mm larger than the width of the timing belt to ensure that the timing belt can be stably installed on the timing pulley to avoid side slip or deviation during the transmission process, which can effectively reduce the deviation and wear of the timing belt.

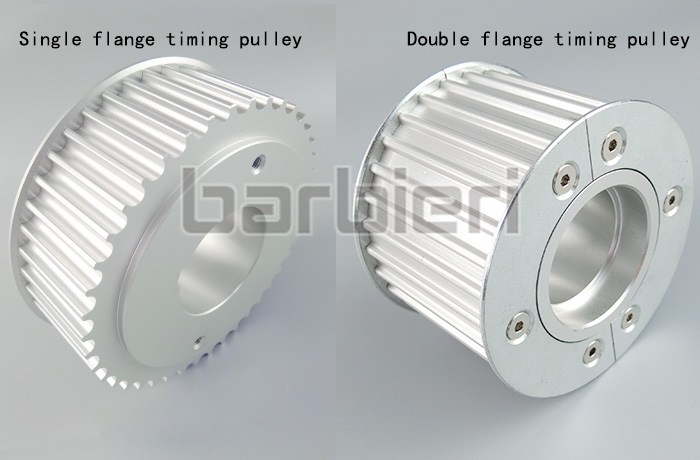

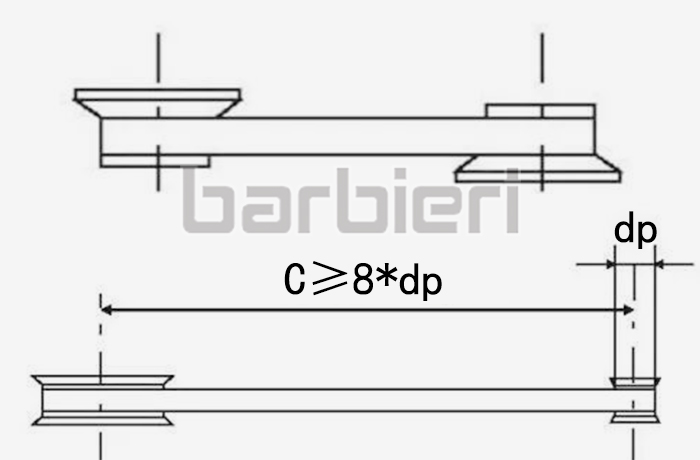

2. When the timing pulley shaft spacing is less than 8 times the timing pulley diameter, one of the timing pulleys can be driven with flanges on both sides; or two timing pulleys can be driven with single-sided flanges on opposite sides; when the timing pulley shaft spacing (C) is greater than or equal to 8 times the timing pulley diameter (d p), the two timing pulleys are driven with flanges on both sides to provide more stable support and guidance, further reducing the deviation and wear of the timing belt.

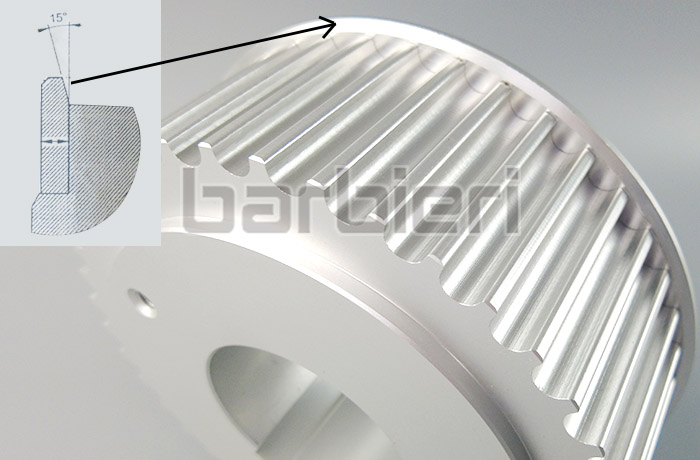

3. The shape design of the timing pulley flange, in order to prevent abnormal wear of the timing belt side or the timing belt climbing up the synchronous wheel flange, it is necessary to set an escape angle on the flange. The escape angle is recommended to be 8-25°, so as to effectively prevent abnormal wear and climbing of the timing belt.

4. Correctly install the timing belt and timing pulley. Improper installation is the main reason for the deviation of the timing belt during transmission. Non-parallel axes will lead to uneven pressure. The frame supporting the timing pulley must have sufficient rigidity, otherwise the timing pulley will cause the two axes to be non-parallel during operation. The two rotating axes should be kept parallel as much as possible to ensure uniform force on the timing belt.

The flanged synchronous wheel design can effectively prevent the deviation and wear of the synchronous belt during use through the above measures, improve the transmission efficiency and system stability, extend the service life of the synchronous belt, and ensure the high efficiency and safety of the transmission efficiency.

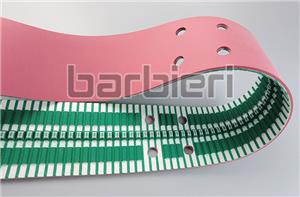

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt