Industrial Belt Drives and Types

Industrial belts are divided into three categories: industrial transmission belts, automotive transmission belts and conveyor belts. According to the classification of belt drives, they can be divided into the following categories:

1. Divided by use:

(1) Transmission belt: used to transmit power

(2) Conveyor belt: used to transport items

2. According to the transmission principle, it is divided into:

(1) Friction belt transmission: The transmission is realized by the friction between the transmission belt and the pulley. Such as: flat belt, V belt, round belt.

(2) Meshing belt transmission: The transmission is realized by meshing the inner teeth of the belt with the tooth grooves on the outer edge of the pulley. Example: timing belt.

3. According to the cross-sectional shape of the belt, it is divided into:

(1) Flat belts: PU flat belts, PVC belts, etc, also known as Flat drive belt, are common conveyor belts, usually used for carrying and transporting materials .

(2) V-belt: A V-belt is a belt with a V-shaped groove. Under the same tension and the same friction coefficient, the friction generated by the V-belt is greater than that of the flat belt. Therefore, The V-belt has strong transmission capacity and more compact structure, and is the most widely used in mechanical transmission.

(3) Multi-ribbed belt: Multi-ribbed belt has a number of longitudinal wedge-shaped protrusions on the base of the flat belt. It has the advantages of both flat belt and V-belt and makes up for its shortcomings. It is mostly used in high-power transmission with compact structure.

(4) Round belt: The cross-sectional shape of the round belt is circular, and the round belt transmission is a friction belt transmission. The friction force generated between the round belt and the contact surface of the driving wheel makes the round belt move, and at the same time, the belt is driven by the contact surface with the driven wheel. The frictional force drives the driven wheel to rotate, thereby transmitting motion and power.

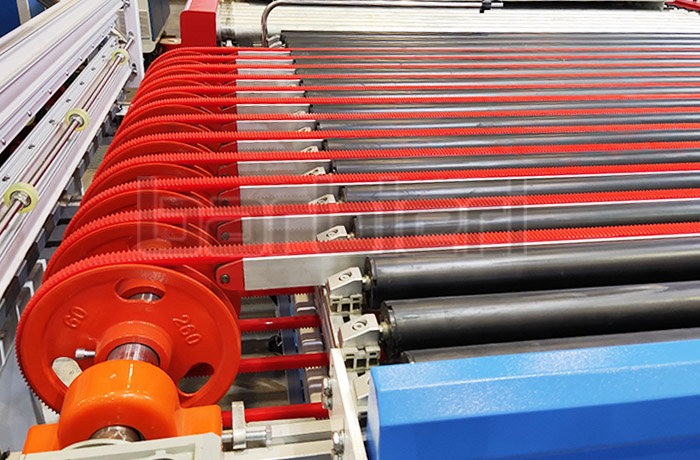

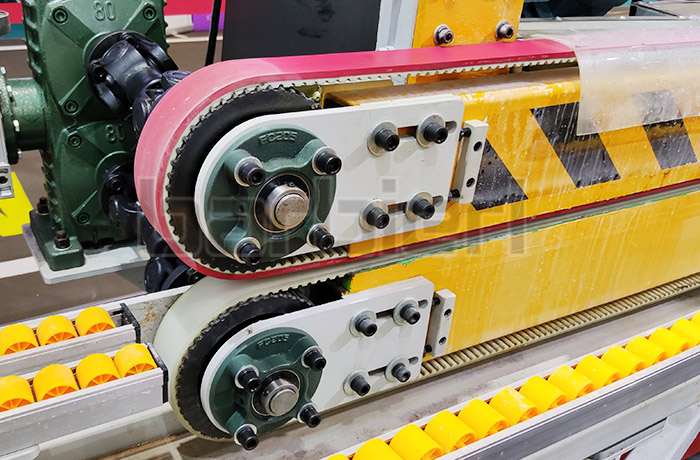

(5) Timing belt: The working surface of the belt is made into a tooth shape, and the rim surface of the pulley is also made into a corresponding tooth shape. The belt and the pulley are mainly driven by meshing, which is a meshing type transmission belt. Can maintain accurate synchronization, they are widely used in high-precision transmission equipment.

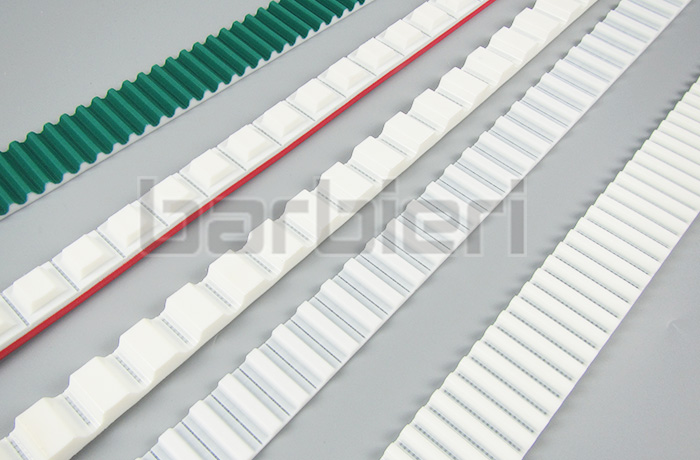

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt