Difference between steel core timing belt and Kevlar core timing belt

Many customers ask: Which is better, steel wire timing belt or wire timing belt? Today I will answer for you.

At present, in the field of industrial belts, there are two types of rubber timing belts and polyurethane

timing belts (PU timing belts): the rope core of the rubber timing belt is: glass fiber rope core; only the

polyurethane timing belt (PU timing belt) Choose different wire cores, generally galvanized steel wire

core, stainless steel wire core, and Kevlar rope core.

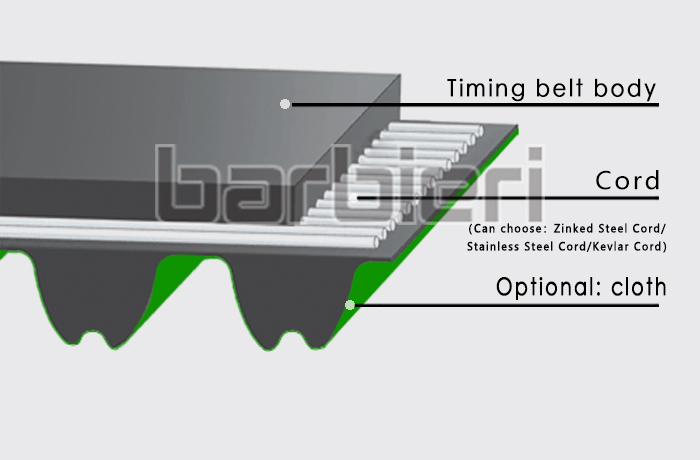

The structure of the timing belt:

1. Zinked steel cord timing belt: Zinked steel cord timing belt is the steel wire core timing belt we usually

use. The steel wire core in the middle layer can enhance the strength and rigidity of the belt, so that the

belt has good dimensional stability. It is guaranteed that the product still maintains good movement

ability in transmission and can withstand large tension and load. This kind of timing belt shows good

wear resistance and durability in the environment of high load and high speed.

Stainless steel cord timing belts are more commonly used, and the price is relatively cheaper than timing

belts with Kevlar cores. Timing belts with steel cords are not as flexible as timing belts with Kevlar cores.

The size of the pulley must meet the minimum number of teeth. Require.

2.Kevlar core timing belt: The advantage is that it is lighter and more flexible. The softness of the core

makes the timing belt better adapt to the curve transmission or occasions that require a smaller bending

radius. Kevlar core timing belt The belt winding performance is better than that of the steel cord timing

belt. It is superior in some industries that require no magnetic field interference, light belt body weight,

and high vibration noise and precision requirements during transmission.

3.Stainless steel cord timing belt: Stainless steel cord timing belt is specially customized and has appli-

cations in some special industries. For example: shipbuilding, mining, chemical industry, etc. In these

industries, with high corrosion resistance and high temperature resistance, it is often necessary to resi-

st the erosion of harsh environments and high-load conditions. The Stainless steel cord timing belt is

an ideal choice to meet these needs. It can withstand harsh environments Stable operation in a chem-

ical environment to ensure the normal operation of production equipment.

Stainless steel cord timing belts and Zinked steel cord timing belts are indistinguishable in appearance,

but there are differences in magnetism. Stainless steel cord timing belts are not magnetic, while Zinked

steel cord timing belts are magnetic.

Steel core timing belts and Kevlar cord timing belts each have certain advantages, which need to be

determined according to the specific application environment and needs. If your application scenario

requires high strength and stability of the timing belt, it may be more suitable to choose a steel wire

core. The advantage of the steel wire core lies in its high load-bearing capacity and tensile strength,

so in some heavy-duty or high-speed transmission occasions, the steel wire core may be able to better

meet the demand; while the wire core is suitable for some applications that require higher flexibility.

In the case of high performance and bending performance, the Kevlar core is relatively soft and can

better adapt to bending, torsion and other motion requirements. Therefore, in some applications that

require bending and deformation, a Kevlar cord may be more suitable.