Matters needing attention when designing timing belt with cleats

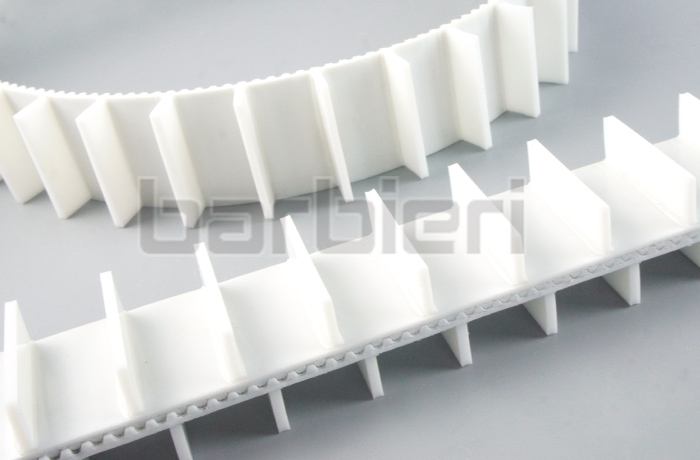

Polyurethane timing belts can be designed with cleats to meet the application of conveying, handling and positioning and other occasions. The cleats are made of the same material as the timing belts, thus guaranteeing maximum strength. Timing belts with cleats can synchronously convey products at high speed and with low noise, ensuring that products move at the correct time, position and sequence. Adding cleats to the timing belt requires a reasonable design of the stopper pitch and position to obtain maximum flexibility and make the timing belt last longer!

Pitch: It is recommended to select the cleats pitch according to the timing belt tooth shape or number of teeth, so that the impact of the timing belt total length tolerance on the cleats interval can be minimized.

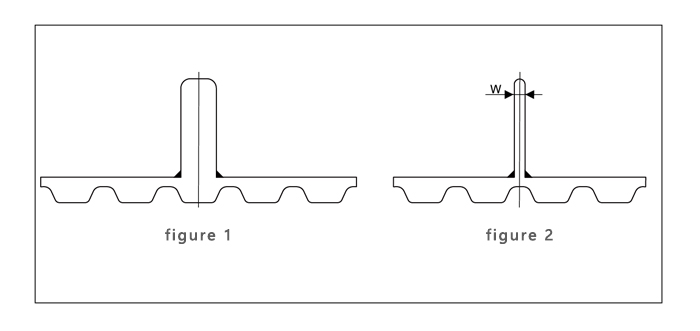

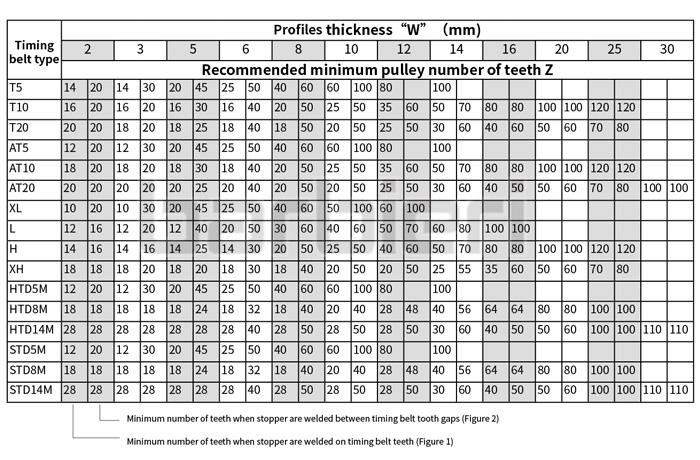

The cleats are located on the timing belt teeth (figure1), where the timing belt achieves maximum flexibility.

The position of the cleats is between the gaps of the teeth of the timing belt (figure2). The timing belt will be limited by the connecting cleats. It is recommended to choose a "W" shaped stopper with the minimum allowable thickness.

Barbieri polyurethane timing belt has the characteristics of high wear resistance, stable size, and good weldability. It is suitable for welding various special specifications of stoppers and meets the production needs of various industries.

1. Single timing belt conveying: customize cleats specifications and spacing according to the size and shape of conveyed products, and install cleats on a single timing belt for conveying;

2. Simultaneous conveying of multiple timing belts: customize cleats specifications and spacing according to the size and shape of the conveyed products, and install cleats on multiple timing belts for synchronous conveying;

3. Accurate positioning of transmission: When the equipment needs to be sensed according to a certain distance, install cleats according to this distance to achieve accurate sensing effect, such as the conveyor belt of the inkjet printer;

4. Timing belt cleats installed with screws: cleats with single or multiple nuts can be welded on the back of the timing belt. The cleats have good stability, the nuts will not fall off, and the positioning is accurate;

5. The use of machinery requires special purposes: various special cleats can be developed and produced according to customer design needs.

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt