What materials are the timing belts made of? Which timing belt is better and more durable?

There are two types of timing belts: Rubber timing belt and Polyurethane timing belt. It is not possible to compare the two timing belts with different materials to judge which one is better or worse. Both rubber timing belts and polyurethane timing belts have their own advantages. The appropriate timing belt should be selected according to the specific application scenario.

The rubber timing belt is made of chloroprene rubber as the main raw material, with a variety of auxiliary materials for different purposes, glass fiber rope as the skeleton material, and nylon high-elastic cloth on the surface of the belt teeth.

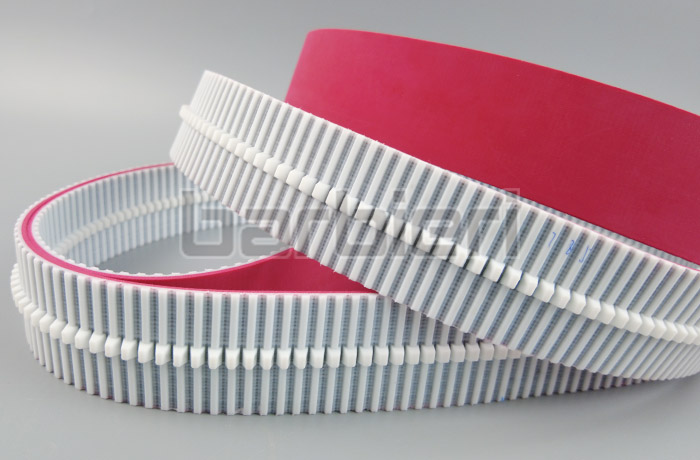

The polyurethane timing belt, also known as the PU timing belt, is made of polyurethane as the production raw material, with a steel wire core or Kevlar core as the strength layer. Nylon cloth can also be added to the back of the tooth surface, surface glue can be added to the back, and special processing can be performed.

Rubber timing belt | Polyurethane timing belt |

Normal operating temperature -35℃ to +80℃ (can withstand up to +115℃ for a short period of time) | Normal operating temperature -10℃ to +60℃ (can withstand up to +80℃ for a short period of time) |

Good wear resistance, but slightly inferior to polyurethane timing belt | Higher wear resistance, suitable for high wear environments |

Running wear will generate dust. In harsh environmental conditions with large changes in temperature and humidity, it is better to use rubber timing belts. | It has higher hardness than rubber timing belts, is more wear-resistant, and is not prone to generating dust. It can be used in the food and pharmaceutical industries. |

The price is relatively economical | Relatively high price |

Polyurethane timing belt: high wear resistance, strong wear resistance, aging resistance, not easy to shed powder, more environmentally friendly, can meet the requirements of health and medical care, more suitable for food, medical industry clean workshop and automation equipment industry than rubber timing belt.

In general, polyurethane timing belt is recommended for high cleanliness, high precision, high load, high speed and long service life.

Rubber timing belt: The wear resistance is not as good as the polyurethane timing belt. The operation wear will produce dust and it is easy to be stretched. However, the hydrolysis resistance, heat resistance and impact resistance of the rubber timing belt are better than those of the polyurethane timing belt. It is better to use rubber timing belt under harsh environmental conditions with large temperature and humidity changes.

Commonly used in medium and low speed transmission and small load working environment, its advantages are relatively low price, easy installation and maintenance, and suitable for some mechanical equipment with relatively low transmission requirements.

- Polyurethane Timing Belt

- Annular Timing Belt

- Open-end Timing Belts

- AT-series Timing Belts

- T-series Timing Belts

- STD-series Timing Belts

- HTD-series Timing Belts

- RPP-series Timing Belts

- TT5-series Timing Belts

- Imperial Series Timing Belt

- Supported Polyurethane Flat Belt Series

- Double Sided Timing Belt

- ATN-series Timing Belts

- Timing Belt With Backing

- Timing Belt With Fabric

- Timing Belt Punching

- Polyurethane Self-tracking Timing Belt

- Polyurethane Belt With Profile

- Special Processing Timing Belt