Polyurethane Timing Belt

-

Polyamide nylon fabric antistatic belt

Barbieri® Antistatic timing belt: Made of thermoplastic polyurethane, with a high-strength steel wire core embedded inside, and the polyamide nylon fabric on the tooth surface and back is antistatic.

Email Details -

Timing belt tooth surface with polyamide fabric

Barbieri® Timing belt with PAZ: Timing belt nylon fabric on teeth reduces noise, there is a buffer zone between Timing belt with PAZ and the pulley, so that they are no longer mechanical movement when meshing transmission, effectively reducing Friction coefficient to achieve the effect of reducing noise. Various coverings can be added to the back of the timing belt according to customer requirements.

Email Details -

Timing belt back with polyamide fabric

Barbieri® Timing belt with PAR: Made of thermoplastic polyurethane, with high-strength steel wire core embedded inside, a layer of wear-resistant PU and a layer of nylon fabric are added to the back of the timing belt, so that the timing belt strengthens the resistance to pull and tear, and the back is nylon Fabric, effective anti-slip, anti-pollution protection product delivery function, etc.

Email Details -

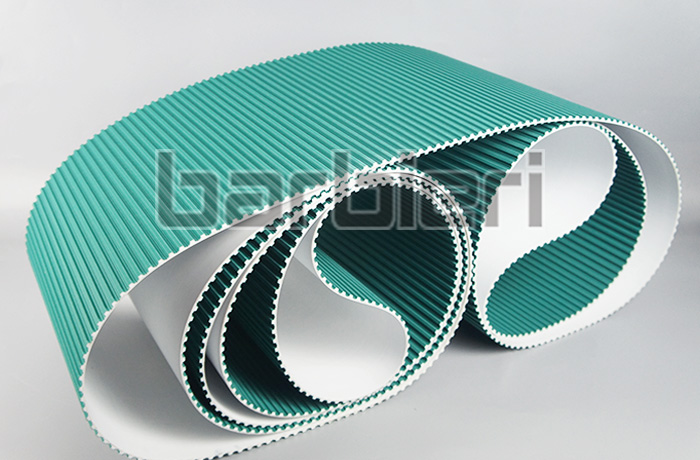

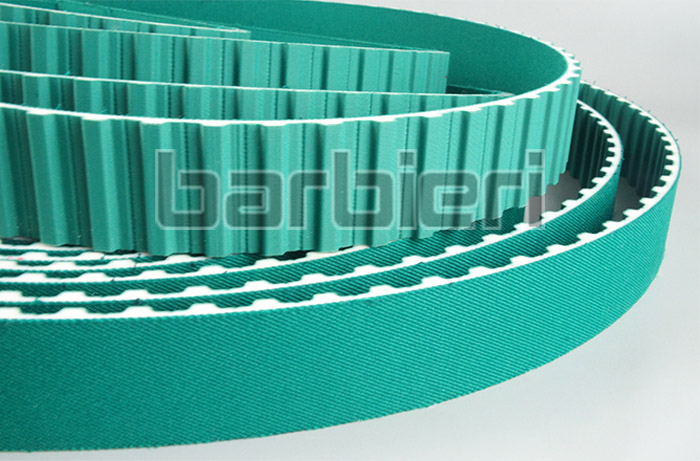

Timing belt tooth and back with polyamide fabric

Barbieri® Timing belt with PAZ -PAR: PU timing belt tooth surface plus nylon surface can effectively reduce the friction coefficient, enhance the meshing of the belt and pulley, reduce noise and vibration; add nylon surface on the back can effectively prevent slipping, pollution, and most oils Protect product delivery, etc. Usually a layer of PU is added to the back of the timing belt to increase the surface friction of the timing belt, the tensile strength of the timing belt, and prolong the service life.Double-sided green cloth timing belts have been widely used in photovoltaic industry component transportation and automatic assembly lines.

Email Details -

Integrated Double-sided Nylon Cloth Clip PU Adhesive Timing Belt

Barbieri® Integrated double-sided nylon timing belt: made of thermoplastic polyurethane, embedded with high-strength steel wire core, the PU layer in the middle of the timing belt increases the resistance to pull and tear, effectively prolonging the service life, without worrying about degumming; PU glue The one-piece molding with the bottom belt is very firm. It adopts one-piece molding technology, high-quality materials and many years of industry experience. The double-cloth one-piece laminated timing belt is a very popular timing belt for users.

Integrated double-sided nylon timing belt Timing belt with nylon fabric Nylon fabric with PU on back of timing beltEmail Details -

White AT Toothed Steel Cords TPU Timing Belt

Barbieri®AT toothed timing belt: made of thermoplastic polyurethane, embedded with high-strength steel wire core, high quality, high wear resistance, and can run smoothly under high load.

Email Details

Polyamide cloth can be added to the back and tooth surfaces as required to reduce friction coefficient, reduce noise and improve belt tooth meshing. -

T Toothed Open Ended Polyurethane Synchronous Belt Coils

Barbieri® T toothed timing belt: made of thermoplastic polyurethane, embedded with high-strength steel wire core, high quality, high wear resistance, and can run smoothly under high load.

Email Details

Polyamide cloth can be added to the back and tooth surfaces as required to reduce friction coefficient, reduce noise and improve belt tooth meshing. -

STD Toothed PU Timing Belt

Barbieri® STD toothed timing belt: made of thermoplastic polyurethane, embedded with high-strength steel wire core, high quality, high wear resistance, and can run smoothly under high load.

Email Details

Polyamide cloth can be added to the back and tooth surfaces as required to reduce friction coefficient, reduce noise and improve belt tooth meshing. -

HTD Toothed Industrial Circle-arc Tooth Timing Belt

Barbieri® HTD toothed timing belt: made of thermoplastic polyurethane, embedded with high-strength steel wire core, high quality, high wear resistance, and can run smoothly under high load.

Email Details

Polyamide cloth can be added to the back and tooth surfaces as required to reduce friction coefficient, reduce noise and improve belt tooth meshing.