synchronous belt

-

Glass Gluing Machine Synchronous Belt With Red "V" Profile

Barbieri® Synchronous belt with "V" stopper: Made of thermoplastic polyurethane, embedded with high-strength steel core, wear-resistant and durable, stable performance, and can run smoothly under high load. It is the synchronous belt of the glass gluing machine. The "v" block is firmly welded to the back of the synchronous belt by hot melting. The block has good stability, which ensures the smooth operation of the glass and the straightness of the sealant will be better.

Synchronous belt with "V" stopper Synchronous belt of glass gluing machine Hollow glass gluing machine timing belt Timing belt for insulating glass sealant machineEmail Details -

Process The High-quality Synchronous Belt According To Drawing

Barbieri®According to customer demand for special processing:back grinding、edge grinding、profiles、covering open window、covering grinding window、covering transverse 、groove、v-groove、half covering、 milling teeth、guide bar、 perforation,and other special customized to meet customer requirements.

Email Details -

Vacuum Synchronous Belt For Glass Edging Machine

Barbieri® Vacuum synchronous belt: made of thermoplastic polyurethane, embedded with high-strength steel wire core, good quality, high wear resistance, and can run smoothly under high load.

Email Details -

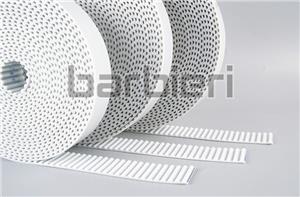

Perforated Timing Belt

Barbieri® Perforated timing belt: made of thermoplastic polyurethane, embedded with high-strength steel wire core, high quality, high wear resistance, and can run smoothly under high load. Timing belt processing countersinks, oblique holes, straight holes and slotting, etc., tooth surface milling to remove teeth, effectively ensuring the quality of adsorption during the transfer process, while improving production efficiency, and can be specially processed according to customer needs.

Email Details -

Annular Jointed Endless PU Timing Belt

Barbieri®Polyurethane Timing belts are manufactured in thermoplastic polyurethane,that gives superior wear and abrasion resistance, Steel cord offer good running characteristics , even with high loads. Polyamide Fabric backing on both tooth and back side allow a reduction of the friction coefficient and when applied on teeth, decrease noise in high speed drives. Advantages of jointed endless timing belt: It can be connected to various lengths and widths according to customer requirements within the processing limit.

Email Details -

Annular Truly Endless Industrial Timing Belt

Barbieri®-flex Truly endless timing belt has no joints, the strength of the whole belt is consistent, and the molding length is stable. It is very suitable for various transmission applications with high performance requirements. Our company can produce CPU truly endless timing belt or TPU truly endless timing belt, both of which are formed by mold.

truly endless toothed belt Industrial synchronous belt Truly endless timing belt CPU truly endless timing beltEmail Details -

Open Ended Timing Belt With Zinked Steel Cords

Barbieri® Open ended timing belt with zinked steel cords is made of thermoplastic polyurethane material, which has high wear resistance, and is embedded with parallel high-strength steel wire cores to ensure that the belt maintains good movement ability during transmission. The production tolerance is small. During the production process, a layer of green cloth can be added on the tooth surface and the tooth back to reduce the noise during operation, and a layer of polyurethane can be added on the back of the belt to prevent corrosion or high load.

Email Details -

Kevlar Cords Polyurethane Coil Material

Barbieri® Kevlar timing belt: The belt body is made of thermoplastic polyurethane material, which has high abrasion resistance, anti-skid, environmental protection and wear resistance. Kevlar rope core is embedded in it, and the tooth has high shear strength. Good abrasion resistance and oil resistance.

Email Details -

High Cost-effective TPU Timing Belt

Barbieri® TPU timing belt: made of thermoplastic polyurethane material, with high wear resistance, embedded parallel high-strength steel wire core, to ensure that the belt maintains good movement ability during transmission. Timing belts can choose to add a layer of green cloth on the tooth surface and back to reduce the noise during operation; you can add a layer of polyurethane on the back of the timing belt to prevent corrosion or high load; you can also choose special custom processing.

Email Details